FLY

Standard :-

- In accordance with ISO 6722.

Application :-

- These are standard wall auto cables ideal for use in automotive and

marine.

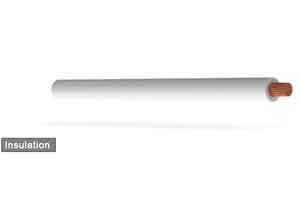

Cable Construction :-

- Soft annealed electrolytic copper Cu-ETP according to DIN EN 13602.

- Conductor construction according to ISO 6722.

- PVC insulation, Cl. B to ISO 6722.

- Packing : Packing available in 100 mtr.

- Longer length in spools or wooden drums

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the suffix

(in place of ‘xx’) for the colour required as per the list: 01 – green,

02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Part Number |

Nominal Cross Sectional Area (Sq. mm)

|

No. of Strands |

Max. Strand Diameter (mm) |

Nominal Conductor Diameter (mm) |

Max. DC Conductor Resistance at 20 C

(Ω/km) |

Nominal Insulation Thickness (mm) |

Overall Diameter |

| (Min.) |

(Max.) |

| 09010101xx30 |

0.5 |

16 |

0.21 |

1.0 |

37.1 |

0.6 |

2.0 |

2.3 |

| 09010102xx30 |

0.75 |

24 |

0.21 |

1.2 |

24.7 |

0.6 |

2.2 |

2.5 |

| 09010103xx30 |

1 |

32 |

0.21 |

1.35 |

18.5 |

0.6 |

2.4 |

2.7 |

| 09010104xx30 |

1.5 |

30 |

0.26 |

1.7 |

12.7 |

0.6 |

2.7 |

3.0 |

| 09010105xx30 |

2 |

40 |

0.26 |

2.0 |

9.42 |

0.6 |

2.9 |

3.3 |

| 09010106xx30 |

2.5 |

50 |

0.26 |

2.2 |

7.6 |

0.7 |

3.3 |

3.6 |

| 09010107xx30 |

3 |

60 |

0.26 |

2.4 |

6.15 |

0.7 |

3.5 |

3.9 |

| 09010108xx30 |

4 |

56 |

0.31 |

2.75 |

4.71 |

0.8 |

4.0 |

4.4 |

| 09010109xx30 |

6 |

84 |

0.31 |

3.3 |

3.14 |

0.8 |

4.6 |

5.0 |

| 09010110xx30 |

10 |

80 |

0.41 |

4.5 |

1.82 |

1.0 |

6.0 |

6.5 |

| 09010111xx30 |

16 |

126 |

0.41 |

6.3 |

1.16 |

1.0 |

7.0 |

8.3 |

| 09010112xx30 |

25 |

196 |

0.41 |

7.8 |

0.743 |

1.3 |

8.7 |

10.2 |

| 09010113xx30 |

35 |

276 |

0.41 |

9.0 |

0.527 |

1.3 |

10.0 |

10.7 |

| 09010114xx30 |

50 |

400 |

0.41 |

10.5 |

0.368 |

1.5 |

11.9 |

13.0 |

| 09010115xx30 |

70 |

560 |

0.41 |

12.5 |

0.259 |

1.5 |

14.0 |

15.0 |

| 09010116xx30 |

95 |

740 |

0.41 |

14.8 |

0.196 |

1.6 |

15.4 |

16.2 |

| 09010117xx30 |

120 |

960 |

0.41 |

16.5 |

0.153 |

1.6 |

18.7 |

19.7 |

FLYY

Standard :-

- In accordance with ISO 6722.

Application :-

- These cables are ideal for use in automotive and marine applications

where higher current carrying capacity and mechnical strength are

required.

Cable Construction :-

- Soft annealed electrolytic copper Cu-ETP according to DIN EN 13602.

- Conductor construction according to ISO 6722.

- PVC insulation, Cl. B to ISO 6722.

- Packing : Packing available in 100 mtr.

- Longer length in spools or wooden drums

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the suffix

(in place of ‘xx’) for the colour required as per the list: 01 – green,

02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Part Number |

Nominal Cross Sectional Area (Sq. mm)

|

No. of Strands |

Max. Strand Diameter (mm) |

Nominal Conductor Diameter (mm) |

Max. DC Conductor Resistance at 20 C

(Ω/km) |

Nominal Insulation Thickness (mm) |

Nominal Core Diameter (mm) |

Sheath Thickness (mm) |

Overall Diameter |

| (Min.) |

(Max.) |

| 09020101xx31 |

0.5 |

16 |

0.21 |

1.0 |

37.1 |

0.6 |

2.1 |

0.4 |

2.7 |

3.1 |

| 09020102xx31 |

0.75 |

24 |

0.21 |

1.2 |

24.7 |

0.6 |

2.3 |

0.4 |

3.0 |

3.3 |

| 09020103xx31 |

1 |

32 |

0.21 |

1.35 |

18.5 |

0.6 |

2.5 |

0.4 |

3.2 |

3.6 |

| 09020104xx31 |

1.5 |

30 |

0.26 |

1.7 |

12.7 |

0.6 |

2.8 |

0.5 |

3.7 |

4.1 |

| 09020105xx31 |

2 |

40 |

0.26 |

2.0 |

9.42 |

0.6 |

3.0 |

0.5 |

3.9 |

4.3 |

| 09020106xx31 |

2.5 |

50 |

0.26 |

2.2 |

7.6 |

0.7 |

3.5 |

0.5 |

4.3 |

4.8 |

FLRY-A

Standard :-

- In accordance with DIN VDE 72 551 Part 5 & 6 and ISO 6722.

Application :-

- These thin-wall automotive cables are ideal for use in automotive and

marine applications where its reduced insulation thickness and higher

current carrying capacity both help to reduce weight and volume in

complex wiring harnesses.

Cable Construction :-

- Soft annealed electrolytic copper Cu-ETP according to DIN EN 13602.

- Conductor construction according to ISO 6722.

- PVC insulation, Cl. B to ISO 6722.

- Packing : Packing available in 100 mtr.

- Longer length in spools or wooden drums

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the suffix

(in place of ‘xx’) for the colour required as per the list: 01 – green,

02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Part Number |

Nominal Cross Sectional Area (Sq. mm)

|

No. of Strands |

Max. Strand Diameter (mm) |

Nominal Diameter of Conductor (mm) |

Max. DC Conductor Resistance at 20 C (Ω/km) |

Nominal Insulation Thickness (mm) |

Nominal Overall Diameter (mm) |

|

Bare/Tinned |

| (Min.) |

(Max.) |

| 09030101xx30 |

0.22 |

7 |

0.21 |

0.7 |

77.9/- |

84.8/86.5 |

0.2 |

1.2 |

| 09030102xx30 |

0.35 |

7 |

0.26 |

0.8 |

47.8/- |

52.0/54.5 |

0.2 |

1.3 |

| 09030103xx30 |

0.5 |

19 |

0.19 |

1.0 |

34.1/- |

37.1/38.2 |

0.22 |

1.6 |

| 09030104xx30 |

0.75 |

19 |

0.23 |

1.2 |

22.7/- |

24.7/25.4 |

0.24 |

1.9 |

| 09030105xx30 |

1 |

19 |

0.26 |

1.35 |

17.0/- |

18.5/19.1 |

0.24 |

2.1 |

| 09030106xx30 |

1.5 |

19 |

0.32 |

1.7 |

11.7/- |

12.7/13.0 |

0.24 |

2.4 |

| 09030107xx30 |

2 |

19 |

0.37 |

2.0 |

8.66/- |

9.42/9.69 |

0.28 |

2.8 |

| 09030108xx30 |

2.5 |

19 |

0.41 |

2.2 |

7.0/- |

7.60/7.80 |

0.28 |

3.0 |

FLRY-B

Standard :-

- In accordance with DIN VDE 72 551 part 5 & 6 and ISO 6722

Application :-

- These thin-wall automotive cables are ideal for use in automotive and

marine applications where its reduced insulation thickness and higher

current carrying capacity both help to reduce weight and volume in

complex wiring harnesses.

Cable Construction :-

- Soft annealed electrolytic copper Cu – ETP according to DIN EN 13602.

- Conductor construction according to ISO 6722. (Concentric conductor,

Type A).

- PVC insulation, Cl. B to ISO 6722.

- Packing : Packing available in 100m.

- Longer length in spools or wooden drums

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the suffix

(in place of ‘xx’) for the colour required as per the list: 01 – green,

02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Part Number |

Nominal Cross Sectional Area (Sq. mm)

|

No. of Strands |

Max. Strand Diameter (mm) |

Nominal Diameter of Conductor (mm) |

Max. DC Conductor Resistance at 20 C (Ω/km) |

Nominal Insulation Thickness (mm) |

Nominal Overall Diameter (mm) |

|

Bare/Tinned |

| (Min.) |

(Max.) |

| 09040101xx30 |

0.35 |

12 |

0.21 |

0.9 |

47.8/- |

52.0/54.5 |

0.2 |

1.4 |

| 09040102xx30 |

0.5 |

16 |

0.21 |

1.0 |

34.1/- |

37.1/38.2 |

0.22 |

1.6 |

| 09040103xx30 |

0.75 |

24 |

0.21 |

1.2 |

22.7/- |

24.7/25.4 |

0.24 |

1.9 |

| 09040104xx30 |

1 |

32 |

0.21 |

1.35 |

17.0/- |

18.5/19.1 |

0.24 |

2.1 |

| 09040105xx30 |

1.5 |

30 |

0.26 |

1.7 |

11.7/- |

12.7/13.0 |

0.24 |

2.4 |

| 09040106xx30 |

2 |

30 |

0.31 |

2.0 |

8.6/- |

9.42/9.69 |

0.28 |

2.8 |

| 09040107xx30 |

2.5 |

50 |

0.26 |

2.2 |

7.0/- |

7.60/7.80 |

0.28 |

3 |

| 09040108xx30 |

3 |

45 |

0.31 |

2.4 |

5.8/- |

6.15/6.36 |

0.28 |

3.2 |

| 09040109xx30 |

4 |

56 |

0.31 |

2.75 |

4.32/- |

4.7/4.8 |

0.32 |

3.7 |

| 09040110xx30 |

6 |

84 |

0.31 |

3.3 |

2.85/- |

3.1/3.2 |

0.32 |

1.3 |

| 09040111xx30 |

10 |

80 |

0.41 |

4.5 |

– / – |

1.82/1.85 |

0.48 |

6 |

| 09040112xx30 |

16 |

126 |

0.41 |

6.3 |

– / – |

1.16/1.18 |

0.52 |

7.9 |

| 09040113xx30 |

25 |

196 |

0.41 |

7.8 |

– / – |

0.743/0.757 |

0.52 |

9.4 |