Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey, 07 – white.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Number *Nominal Dia. of Strands | Approx. Overall Diameter (mm) | Max. DC Conductor Resistance at 20OC (Ω/km) | Current Rating (Amps) | |

|---|---|---|---|---|---|---|---|

| Casing | Concealed | ||||||

| 01010101xxy0 | 0.5 | 0.6 | 16/0.2 | 2.1 | 39.0 | 5 | 4 |

| 01010102xxy0 | 0.75 | 0.6 | 24/0.2 | 2.3 | 26.0 | 9 | 8 |

| 01010103xxy0 | 1 | 0.7 | 14/0.3 | 2.7 | 18.1 | 14 | 13 |

| 01010104xxy0 | 1.5 | 0.7 | 22/0.3 | 3.0 | 12.1 | 18 | 16 |

| 01010105xxy0 | 2.5 | 0.8 | 36/0.3 | 3.7 | 7.41 | 24 | 20 |

| 01010106xxy0 | 4 | 0.8 | 56/0.3 | 4.1 | 4.95 | 30 | 26 |

| 01010107xxy0 | 6 | 0.8 | 84/0.3 | 4.6 | 3.30 | 38 | 33 |

| 01010108xxy0 | 10 | 1.0 | 140/0.3 | 7.0 | 1.91 | 52 | 45 |

| 01010109xxy0 | 16 | 1.0 | 126/0.4 | 8.1 | 1.21 | 70 | 60 |

| Test | Test Method | Values |

|---|---|---|

| Limited Oxygen Index | IS 10810 P-58 | > 29% |

| Limited Temp. Index | IS 10810 P-64 | >250 °C |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Number *Nominal Dia. of Strands | Approx. Overall Diameter (mm) | Max. DC Conductor Resistance at 20OC (Ω/km) | Current Rating (Amps) | |

|---|---|---|---|---|---|---|---|

| Casing | Concealed | ||||||

| 01020101xx50 | 1 | 0.7 | 14/0.3 | 2.7 | 18.1 | 14 | 13 |

| 01020102xx50 | 1.5 | 0.7 | 22/0.3 | 3.0 | 12.1 | 18 | 16 |

| 01020103xx50 | 2.5 | 0.8 | 36/0.3 | 3.7 | 7.41 | 24 | 20 |

| 01020104xx50 | 4** | 0.8 | 56/0.3 | 4.1 | 4.95 | 30 | 26 |

| Test | Test Method | Values |

|---|---|---|

| Limited Oxygen Index | IS 10810 P – 58 | > 29% |

| Limited Temperature Index | IS 10810 P – 64/td> | > 250OC |

| Smoke Density (Light Absorption) | IS 13360 P – 6/Sec 9 | < 60% |

| Acid Gas Generation | IS 10810 P – 59 | < 20% |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey, 07 – white.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Number *Nominal Dia. of Strands | Approx. Overall Diameter (mm) | Max. DC Conductor Resistance at 20OC (Ω/km) | Current Rating (Amps) | |

|---|---|---|---|---|---|---|---|

| Casing | Concealed | ||||||

| 01030101xx40 | 1 | 0.7 | 37/0.20 | 2.6 | 19.5 | 12 | 11 |

| 01030102xx40 | 1.5 | 0.7 | 37/0.22 | 3.0 | 13.3 | 16 | 15 |

| 01030103xx40 | 2.5 | 0.8 | 61/0.22 | 3.6 | 7.98 | 23 | 19 |

| 01030104xx40 | 4 | 0.8 | 61/0.30 | 4.1 | 4.95 | 30 | 26 |

| Test | Test Method | Values |

|---|---|---|

| Limited Oxygen Index | IS 10810 P-58 | > 29% |

| Limited Temperature Index | IS 10810 P – 64/td> | > 250OC |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey, 07 – white.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Number *Nominal Dia. of Strands | Approx. Overall Diameter (mm) | Max. DC Conductor Resistance at 20OC (Ω/km) | Current Rating (Amps) | |

|---|---|---|---|---|---|---|---|

| Casing | Concealed | ||||||

| 01040101xx70 | 1 | 0.7 | 37/0.20 | 2.6 | 19.5 | 12 | 11 |

| 01040102xx70 | 1.5 | 0.7 | 37/0.22 | 3.0 | 13.3 | 16 | 15 |

| 01040103xx70 | 2.5 | 0.8 | 61/0.22 | 3.6 | 7.98 | 23 | 19 |

| 01040104xx70 | 4 | 0.8 | 61/0.30 | 4.1 | 4.95 | 30 | 26 |

| 01040105xx70 | 6* | 0.8 | 84/0.30 | 4.6 | 3.30 | 38 | 33 |

| Test | Test Method | Values |

|---|---|---|

| Limited Oxygen Index | ASTM – D 2863 | ≥ 32% |

| Limited Temp. Index | ASTM – D 2863 | > 250OC |

| Smoke Density (Light Absorption) | ASTM – D 2843 | < 10% |

| Acid Gas Generation | IEC – 60754 – 1 | < 5% |

| Part Number | Cable Type | Cable Size (Sq. mm) | Nominal Cable Diameter (mm) | Power Core Colour |

|---|---|---|---|---|

| 010801010795 | CCTV Cable 4+1 | 4C + 1C x 0.25 | 6.8 | RD, YL, BK, GN |

| 010801020795 | CCTV Cable 3+1 | 3C + 1C x 0.25 | 6.8 | RD, BK, GN |

| Construction Details | Cable Type – Armoured | |||

|---|---|---|---|---|

| RG 59 F | RG 6 F* | RG 11 F | ||

| Part Number | 010501050791 | 010501060791 | 010501070791 | |

| Inner conductor | Copper | Copper | Copper | |

| Nominal Diameter (mm) | 0.8 | 1.02 | 1.63 | |

| Dielectric | Foam PE | Foam PE | Foam PE | |

| Nominal Diameter (mm) | 3.5 | 4.5 | 7.0 | |

| Outer Conductor | First | Bonded Al Tape | Bonded Al Tape | Bonded Al Tape |

| Second | Tinned Cu/Al Braid | Tinned Cu/Al Braid | Tinned Cu/Al Braid | |

| Nominal Coverage (%) | 60 | 60 | 60 | |

| PVC Jacket | Black | Black | Black | |

| Nominal Cable Diameter (mm) | 6.2 | 7.0 | 10.0 | |

| Parameters | Cable Type | ||

|---|---|---|---|

| RG 59 F | RG 6 F* | RG 11 F | |

| Inner Conductor-Max Resistance at 20°C (Ω/100m) | 0.8 | 2.1 | 3.43 |

| Nominal Capacitance (pF/m) | 53 | 53 | 53 |

| Characteristic Impedance (Ω) | 75 | 75 | 75 |

| Velocity of Propagation (%) | 85 | 85 | 85 |

| Dielectric Strength (KV) | > 1 | > 1 | > 1 |

| Minimum Bending Radius (mm) | 75 | 65 | 60 |

| Maximum Attenuation at 20°C (dB/100m) at | Max. | Max. | Max. |

| 5 MHz | 1.2 | 1.9 | 2.8 |

| 50 MHz | 3.1 | 5.3 | 6.7 |

| 100 MHz | 4.2 | 7.0 | 8.8 |

| 200 MHz | 6.0 | 9.9 | 12.4 |

| 250 MHz | 6.7 | 10.5 | 13.4 |

| 300 MHz | 7.3 | 11.5 | 14.6 |

| 350 MHz | 7.9 | 12.4 | 15.7 |

| 400 MHz | 8.5 | 13.3 | 16.7 |

| 450 MHz | 9.0 | 14.3 | 17.7 |

| 500 MHz | 9.5 | 14.9 | 18.7 |

| 550 MHz | 9.9 | 15.7 | 19.5 |

| 600 MHz | 10.4 | 16.4 | 20.3 |

| 750 MHz | 11.9 | 18.3 | 22.8 |

| 800 MHz | 12.4 | 19.5 | 24.5 |

| 900 MHz | 13.0 | 20.1 | 24.7 |

| 1000 MHz | 14.2 | 21.4 | 26.6 |

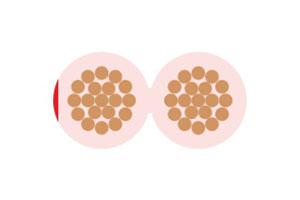

| Part Numbers | Size (mm) | No. of Pairs | Approx. Overall Diameter (mm) |

|---|---|---|---|

| 010600221040 | 0.4 | 2 | 3.9 |

| 010600321040 | 0.4 | 3 | 4.3 |

| 010600421040 | 0.4 | 4 | 4.7 |

| 010600521040 | 0.4 | 5 | 5.2 |

| 010601021040 | 0.4 | 10 | 6.5 |

| 010602021040 | 0.4 | 20 | 9.2 |

| 010600221050 | 0.5 | 2 | 4.2 |

| 010600321050 | 0.5 | 3 | 4.7 |

| 010600421050 | 0.5 | 4 | 5.1 |

| 010600521050 | 0.5 | 5 | 5.7 |

| 010601021050 | 0.5 | 10 | 7.0 |

| 010602021050 | 0.5 | 20 | 10.0 |

| Electrical Parameters | Size | |

|---|---|---|

| 0.5 mm | 0.4 mm | |

| DC conductor resistance | 92.20 Ω/Km at 20°C max. | 143.0 Ω/Km at 20°C max. |

| Mutual capacitance | 50 nF/km max. | |

| Insulation resistance in air | 10000 M-Ω/Km | |

| Capacitance unbalance – pair to pair | 250 pF/100m max. | |

| Capacitance unbalance – pair to ground | 330 pF/100m max. | |

| Resistance unbalance | 5% max. | |

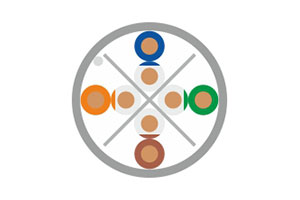

| Type | CAT 5e | CAT 6 | |

|---|---|---|---|

| Part Number | 010701014094 | 010701014194 | |

| Electrical Characteristics at 20OC | Specification | Typical Performance | |

|---|---|---|---|

| CAT 5e | CAT 6 | ||

| Conductor loop resistance | Max. 190/100m | 160/100m | 140/100m |

| Conductor resistance unbalance | Max. 2% | 0.5% | 0.5% |

| Dielectric strength | 1.0 kV DC or 0.7 kV AC for 1 min. | 100% in process test | 100% in process test |

| Insulation resistance | >500MΩ/Kmat100-500Vtestvoltage | >500 MΩ/Km | >500 MΩ/Km |

| Capacitance unbalance to earth | Max. 160 pF/100m | 40 pF/100m | 40 pF/100m |

| Velocity of propagation | <534 nsec/100m at 100MHz | 496 nsec/100m at 100 MHz (NVP for hand held testers = 0.69) | 490 nsec/100m at 100 MHz (NVP for hand held testers = 0.69) |

| Skew | Max. 40 nsec/100m at 100MHz | Max. 25 nsec/100m at 100 MHz | Max. 30 nsec/100m at 100 MHz |

| Mean characteristic impedance | 1000 ±50 at 100 MHZ | 1000 ±30 at 100 MHZ | 1000 ±30 at 100 MHZ |

| Coupling attenuation up to 1 Ghz | Min. 40 dB | 50 dB | 56 dB |

| Type | CAT 5e | CAT 6 | |

|---|---|---|---|

| Part Number | 010701014094 | 010701014194 | |

| Wire Size | 2Ω load | 4Ω load | 6Ω load | 8Ω load |

|---|---|---|---|---|

| 22 AWG | 3ft (0.9m) | 6ft (1.8m) | 9ft (2.7m) | 12ft (3.6m) |

| 19 AWG | 5ft (1.5m) | 10ft (3m) | 15ft (4.5m) | 20ft (6m) |

| 18 AWG | 8ft (2.4m) | 16ft (4.9m) | 24ft (7.3m) | 32ft (9.7m) |

| 16 AWG | 12ft (3.6m) | 24ft (7.3m) | 36ft (11m) | 48ft (15m) |

| 14 AWG | 20ft (6.1m) | 40ft (12m) | 60ft (18m) | 80ft (24m) |

| 12 AWG | 30ft (9.1m) | 60ft (18m) | 90ft (27m) | 120ft (36m) |

| 10 AWG | 50ft (15m) | 100ft (30m) | 150ft (46m) | 200ft (61m) |

| Part Number | No. of Pairs x Nominal Cross-Section (mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 011000221080 | 2 x 2 x 0.8 mm | 7.2 ± 0.5 mm | 20.0 | 68.0 |

| Product Type | Cable Size Range (Sq. mm) | Specifications |

|---|---|---|

| PVC 70°C/HR 85°C | 1 x 0.5 to 630 | IS 694, IS 8130 Class 1 & 2,IS 5831 Type A & C |

| FR 70°C/HR 85°C + FR | 1 x 0.5 to 630 | S 694, IS 8130 Class 1 & 2, IS 5831 Type A & C ( FR ) |

| FR-LSHC | 1 x 0.5 to 630 | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A ( FR-LSH ) |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required as per the list: 02 – black, 03 – red, 04 – blue, 05 – yellow, 07 – white, 12 – grey and (in place of ‘y’) for the insulation material required as per the list: 1 – PVC 70°C, 2 – PVC FR 70°C, 3 – PVC HR 85°C, 4 – PVC HR 85°C + FR, 5 – PVC FR-LSH.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Conductor Class | No. of Conductor | Max. DC Conductor Resistance at 20°C (Ώ/km) | Nominal Insulation Thickness (mm) | Maximum Diameter Over Insulation (mm) |

|---|---|---|---|---|---|---|

| 01110101xxy0 | 0.5 | 1 | 1 | 36.0 | 0.6 | 2.3 |

| 01110102xxy0 | 0.75 | 1 | 1 | 24.5 | 0.6 | 2.5 |

| 01110103xxy0 | 1 | 1 | 1 | 18.1 | 0.6 | 2.7 |

| 01110104xxy0 | 1.5 | 1 | 1 | 12.1 | 0.7 | 3.2 |

| 01110105xxy0 | 2.5 | 1 | 1 | 7.41 | 0.8 | 3.9 |

| 01110106xxy0 | 4 | 1 | 1 | 4.61 | 0.8 | 4.4 |

| 01110107xxy0 | 6 | 1 | 1 | 3.08 | 0.8 | 5.0 |

| 01110108xxy0 | 10 | 1 | 1 | 1.5 | 1.0 | 6.4 |

| Product Type | Specifications |

|---|---|

| PVC 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 sheath |

| HR 85°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 sheath |

| FR 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 ( FR ) sheath |

| HR 85°C + FR | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 (FR) sheath |

| FR-LSH | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 (FR-LSH) sheath |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘y’) for the product type required: 1 – PVC 70°C, 2 – PVC FR 70°C, 3 – PVC HR 85°C, 4 – PVC HR 85°C +FR, 5 – PVC FR-LSH and (in place of ‘z’) for the sheath colour required as per the list: 1 – black, 2 – grey, 3 – white.

| Part Number | No. of Cross | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Nominal Thickness of sheath | Maximum Overall Dimensions (mm) |

|---|---|---|---|---|---|

| 0112010102yz | 1 | 1 | 0.60 | 0.8 | 4.7 |

| 0112010202yz | 2 | 1 | 0.60 | 0.9 | 8.2 |

| 0112010302yz | 3 | 1 | 0.60 | 0.9 | 8.6 |

| 0112010402yz | 4 | 1 | 0.60 | 0.9 | 9.2 |

| 0112010502yz | 1 | 1.5 | 0.60 | 0.8 | 5 |

| 0112010602yz | 2 | 1.5 | 0.60 | 0.9 | 8.8 |

| 0112010702yz | 3 | 1.5 | 0.60 | 0.9 | 9.2 |

| 0112010802yz | 4 | 1.5 | 0.60 | 0.9 | 10.0 |

| 0112010902yz | 1 | 2.5 | 0.80 | 0.8 | 5.8 |

| 0112011002yz | 2 | 2.5 | 0.80 | 1.0 | 10.5 |

| 0112011102yz | 3 | 2.5 | 0.80 | 1.0 | 11.0 |

| 0112011202yz | 4 | 2.5 | 0.80 | 1.0 | 12.0 |

| 0112011302yz | 1 | 4 | 0.80 | 0.9 | 6.8 |

| 0112011402yz | 2 | 4 | 0.80 | 1.0 | 12.0 |

| 0112011502yz | 3 | 4 | 0.80 | 1.1 | 13.0 |

| 0112011602yz | 4 | 4 | 0.80 | 1.1 | 14.0 |

| 0112011702yz | 1 | 6 | 0.80 | 0.9 | 7.8 |

| 0112011802yz | 2 | 6 | 0.80 | 1.1 | 13.5 |

| 0112011902yz | 3 | 6 | 0.80 | 1.1 | 14.5 |

| 0112012002yz | 4 | 6 | 0.80 | 1.2 | 15.5 |

| 0112012102yz | 1 | 10 | 1.00 | 0.9 | 8.8 |

| 0112012202yz | 2 | 10 | 1.00 | 1.2 | 16.5 |

| 0112012302yz | 3 | 10 | 1.00 | 1.2 | 17.5 |

| 0112012402yz | 4 | 10 | 1.00 | 1.3 | 19.5 |

| 0112012502yz | 1 | 16 | 1.00 | 1.0 | 10.5 |

| 0112012602yz | 2 | 16 | 1.00 | 1.3 | 19.0 |

| 0112012702yz | 3 | 16 | 1.00 | 1.3 | 20.0 |

| 0112012802yz | 4 | 16 | 1.00 | 1.4 | 22.5 |

| 0112012902yz | 1 | 25 | 1.20 | 1.1 | 12.5 |

| 0112013002yz | 2 | 25 | 1.20 | 1.4 | 23.0 |

| 0112013102yz | 3 | 25 | 1.20 | 1.5 | 24.5 |

| 0112013202yz | 4 | 25 | 1.20 | 1.6 | 27.5 |

| 0112013302yz | 1 | 35 | 1.20 | 1.1 | 13.5 |

| 0112013402yz | 2 | 35 | 1.20 | 1.5 | 25.5 |

| 0112013502yz | 3 | 35 | 1.20 | 1.6 | 27.5 |

| 0112013602yz | 4 | 35 | 1.20 | 1.7 | 30.5 |

| 0112013702yz | 1 | 50 | 1.40 | 1.2 | 15.5 |

| 0112013802yz | 2 | 50 | 1.40 | 1.6 | 29.5 |

| 0112013902yz | 3 | 50 | 1.40 | 1.7 | 31.5 |

| 0112014002yz | 4 | 50 | 1.40 | 1.8 | 35.0 |

| 0112014102yz | 1 | 70 | 1.40 | 1.4 | 17.5 |

| 0112014202yz | 2 | 70 | 1.40 | 2.4 | 35.0 |

| 0112014302yz | 3 | 70 | 1.40 | 2.5 | 37.0 |

| 0112014402yz | 4 | 70 | 1.40 | 2.8 | 41.4 |

| 0112014502yz | 1 | 95 | 1.60 | 1.5 | 21.0 |

| 0112014602yz | 2 | 95 | 1.60 | 2.7 | 40.5 |

| 0112014702yz | 3 | 95 | 1.60 | 2.9 | 43.2 |

| 0112014802yz | 4 | 95 | 1.60 | 3.1 | 48.1 |

| 0112014902yz | 1 | 120 | 1.60 | 1.5 | 48.1 |

| 0112015002yz | 2 | 120 | 1.60 | 2.9 | 44.0 |

| 0112015102yz | 3 | 120 | 1.60 | 3.1 | 47.3 |

| 0112015202yz | 4 | 120 | 1.60 | 3.4 | 52.8 |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green / yellow, 07 – white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Overall Diameter Lower Limit (mm) | Overall Diameter Upper Limit (mm) | Approx. Net Weight (kg/km) |

|---|---|---|---|---|---|

| 01130101xx60 | 1.5 | 0.70 | 2.70 | 3.40 | 19 |

| 01130102xx60 | 2.5 | 0.80 | 3.30 | 4.10 | 33 |

| 01130103xx60 | 4 | 0.80 | 3.80 | 4.70 | 50 |

| 01130104xx60 | 6 | 0.80 | 4.30 | 5.40 | 74 |

| 01130105xx60 | 10 | 1.00 | 5.60 | 7.00 | 126 |

| 01130106xx60 | 16 | 1.00 | 6.40 | 8.00 | 184 |

| 01130107xx60 | 25 | 1.20 | 8.10 | 10.10 | 295 |

| 01130108xx60 | 35 | 1.20 | 9.00 | 11.30 | 375 |

| 01130109xx60 | 50 | 1.40 | 10.60 | 13.20 | 510 |

| 01130110xx60 | 70 | 1.40 | 12.10 | 15.10 | 710 |

| 01130111xx60 | 95 | 1.60 | 14.10 | 17.60 | 950 |

| 01130112xx60 | 120 | 1.60 | 15.60 | 19.40 | 1240 |

| 01130113xx60 | 150 | 1.80 | 17.30 | 21.60 | 1530 |

| 01130114xx60 | 185 | 2.00 | 19.30 | 24.10 | 1800 |

| 01130115xx60 | 240 | 2.20 | 22.00 | 27.50 | 2500 |

| 01130116xx60 | 300 | 2.40 | 24.50 | 30.60 | 2990 |

| 01130117xx60 | 400 | 2.60 | 27.50 | 34.30 | 3860 |

| 01130118xx60 | 500 | 2.80 | 30.50 | 38.20 | 4900 |

| 01130119xx60 | 630 | 2.80 | 34.00 | 42.50 | 6370 |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green / yellow, 07 – white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Overall Diameter Lower Limit (mm) | Overall Diameter Upper Limit (mm) | Approx. Net Weight (kg/km) |

|---|---|---|---|---|---|

| 01140101xx10 | 1.5 | 0.70 | 2.70 | 3.30 | 19 |

| 01140102xx10 | 2.5 | 0.80 | 3.30 | 4.00 | 33 |

| 01140103xx10 | 4 | 0.80 | 3.80 | 4.60 | 50 |

| 01140104xx10 | 6 | 0.80 | 4.30 | 5.20 | 74 |

| 01140105xx10 | 10 | 1.00 | 5.60 | 6.70 | 126 |

| 01140106xx10 | 16 | 1.00 | 6.40 | 7.80 | 184 |

| 01140107xx10 | 25 | 1.20 | 8.10 | 9.70 | 295 |

| 01140108xx10 | 35 | 1.20 | 9.00 | 10.90 | 375 |

| 01140109xx10 | 50 | 1.40 | 10.60 | 12.80 | 510 |

| 01140110xx10 | 70 | 1.40 | 12.10 | 14.60 | 710 |

| 01140111xx10 | 95 | 1.60 | 14.10 | 17.10 | 950 |

| 01140112xx10 | 120 | 1.60 | 15.60 | 18.80 | 1240 |

| 01140113xx10 | 150 | 1.80 | 17.30 | 20.90 | 1530 |

| 01140114xx10 | 185 | 2.00 | 19.30 | 23.30 | 1800 |

| 01140115xx10 | 240 | 2.20 | 22.00 | 26.60 | 2500 |

| 01140116xx10 | 300 | 2.40 | 24.50 | 29.60 | 2990 |

| 01140117xx10 | 400 | 2.60 | 27.50 | 33.20 | 3860 |

| 01140118xx10 | 500 | 2.80 | 30.50 | 36.90 | 4900 |

| 01140119xx10 | 630 | 2.80 | 34.00 | 41.10 | 6370 |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green / yellow, 07 – white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

| Test | Test Method | Values |

|---|---|---|

| Limited Oxygen Index | IS 10810 P-58 | > 29% |

| Limited Temp. Index | IS 10810 P-64 | >250 °C |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey, 07 – white.

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Overall Diameter Lower Limit (mm) | Overall Diameter Upper Limit (mm) | Approx. Net Weight (kg/km) |

|---|---|---|---|---|---|---|

| 01150101xx10 | 1.5 | 0.70 | 0.8 | 4.20 | 5.00 | 37 |

| 01150102xx10 | 2.5 | 0.80 | 0.8 | 4.80 | 5.70 | 51 |

| 01150103xx10 | 4 | 0.80 | 0.9 | 5.50 | 6.70 | 75 |

| 01150104xx10 | 6 | 0.80 | 0.9 | 6.00 | 7.30 | 98 |

| 01150105xx10 | 10 | 1.00 | 0.9 | 7.30 | 8.80 | 152 |

| 01150106xx10 | 16 | 1.00 | 1.0 | 8.40 | 10.10 | 220 |

| 01150107xx10 | 25 | 1.20 | 1.1 | 10.00 | 12.10 | 336 |

| 01150108xx10 | 35 | 1.20 | 1.1 | 11.10 | 13.50 | 353 |

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Approx Overall Diameter (mm) | Approx. Net Weight (kg/km) |

|---|---|---|---|---|---|

| 011600100004 | 4 | 0.70 | 1.40 | 8.0 | 107 |

| 011600100006 | 6 | 0.70 | 1.40 | 8.5 | 132 |

| 011600100010 | 10 | 0.70 | 1.40 | 9.5 | 181 |

| 0116001000160 | 16 | 0.70 | 1.40 | 10.5 | 247 |

| 011600100025 | 25 | 0.90 | 1.40 | 12.0 | 358 |

| 011600100035 | 35 | 0.90 | 1.40 | 13.0 | 466 |

| 011600100050 | 50 | 1.00 | 1.40 | 14.0 | 545 |

| 011600100070 | 70 | 1.10 | 1.40 | 16.0 | 765 |

| 011600100095 | 95 | 1.10 | 1.50 | 18.0 | 1022 |

| 011600100120 | 120 | 1.20 | 1.50 | 20.0 | 1267 |

| 011600100150 | 150 | 1.40 | 1.60 | 22.0 | 1556 |

| 011600100185 | 185 | 1.60 | 1.60 | 24.0 | 1928 |

| 011600100240 | 240 | 1.70 | 1.70 | 27.0 | 2501 |

| 011600100300 | 300 | 1.80 | 1.80 | 29.0 | 3108 |

| 011600100400 | 400 | 2.00 | 1.90 | 32.0 | 3923 |

| 011600100500 | 500 | 2.20 | 2.00 | 36.0 | 4999 |

| 011600100630 | 630 | 2.40 | 2.20 | 40.0 | 6414 |

| Product Type | Specifications |

|---|---|

| PVC 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 sheath |

| HR 85°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 sheath |

| FR 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 ( FR ) sheath |

| HR 85°C + FR | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 (FR) sheath |

| FR-LSH | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 (FR-LSH) sheath |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘y’) for the product type required: 1 – PVC 70°C, 2 – PVC FR 70°C, 3 – PVC HR 85°C, 4 – PVC HR 85°C +FR, 5 – PVC FR-LSH and (in place of ‘z’) for the sheath colour required as per the list: 1 – black, 2 – grey, 3 – white

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Maximum Overall Dimension (W x H) (mm x mm) |

|---|---|---|---|---|

| 0117110132yz | 0.5 | 0.6 | 0.9 | 7.2 X 4.9 |

| 0117110232yz | 0.75 | 0.6 | 0.9 | 7.8 X 5.2 |

| 0117110332yzz | 1 | 0.6 | 0.9 | 8.0 X 5.4 |

| 0117110432yz | 1.5 | 0.6 | 0.9 | 8.6 X 5.6 |

| 0117110532yz | 2.5 | 0.7 | 1.0 | 10.5 x 6.6 |

| 0117110632yz | 4 | 0.8 | 1.0 | 12.0 X 7.4 |

| 0117110732yz | 6 | 0.8 | 1.1 | 13.0 X 8.0 |

| 0117110832yz | 10 | 1.0 | 1.4 | 16.0 X 9.6 |

| 0117110932yz | 16 | 1.0 | 1.4 | 18.5 X 11.0 |

| 0117111032yz | 25 | 1.2 | 2.0 | 22.5 X 13.0 |

| 0117111132yz | 35 | 1.2 | 2.0 | 25.5 X 14.5 |

| 0117111232yz | 50 | 1.4 | 2.2 | 29.0 X 16.5 |

| Product Type | Specifications |

|---|---|

| PVC 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 sheath |

| HR 85°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 sheath |

| FR 70°C | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 ( FR ) sheath |

| HR 85°C + FR | IS 694, IS 8130 Class 1 & 2, IS 5831 Type C insulation & ST-2 (FR) sheath |

| FR-LSH | IS 694, IS 8130 Class 1 & 2, IS 5831 Type A insulation & ST-1 (FR-LSH) sheath |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘y’) for the product type required: 1 – PVC 70°C, 2 – PVC FR 70°C, 3 – PVC HR 85°C, 4 – PVC HR 85°C +FR, 5 – PVC FR-LSH and (in place of ‘z’) for the sheath colour required as per the list: 1 – black, 2 – grey, 3 – white

| Part Number | Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Maximum Overall Dimension (W x H) (mm x mm) |

|---|---|---|---|---|

| 0117110132yz | 0.5 | 0.6 | 0.9 | 7.2 X 4.9 |

| 0117110232yz | 0.75 | 0.6 | 0.9 | 7.8 X 5.2 |

| 0117110332yzz | 1 | 0.6 | 0.9 | 8.0 X 5.4 |

| 0117110432yz | 1.5 | 0.6 | 0.9 | 8.6 X 5.6 |

| 0117110532yz | 2.5 | 0.7 | 1.0 | 10.5 x 6.6 |

| 0117110632yz | 4 | 0.8 | 1.0 | 12.0 X 7.4 |

| 0117110732yz | 6 | 0.8 | 1.1 | 13.0 X 8.0 |

| 0117110832yz | 10 | 1.0 | 1.4 | 16.0 X 9.6 |

| 0117110932yz | 16 | 1.0 | 1.4 | 18.5 X 11.0 |

| 0117111032yz | 25 | 1.2 | 2.0 | 22.5 X 13.0 |

| 0117111132yz | 35 | 1.2 | 2.0 | 25.5 X 14.5 |

| 0117111232yz | 50 | 1.4 | 2.2 | 29.0 X 16.5 |

| Product Type | Specifications |

|---|---|

| XLPE/PVC | Class 2 (1 to 2.5 Sq. mm) for others class 5 to EN 60228, XLPE insulation & PVC ST-2 sheath |

| Part Number | Conductor Construction | Max. Conductor Resistance at 20OC (Ω/km) | Nominal Insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Approx. Overall Dimensions (W x H) (mm) +/- 0.5 mm | Current Carrying Capacity (Amp.) | |

|---|---|---|---|---|---|---|---|

| Nominal Cross Sectional Area (Sq. mm) | No. of Strands/Max. Strands Dia. (mm) | ||||||

| 011910300001 | 1 | 14/0.3 | 18.1 | 0.7 | 1.0 | 10.6 X 5.2 | 12 |

| 011910301105 | 1.5 | 22/0.3 | 12.1 | 0.7 | 1.0 | 11.6 X 5.5 | 20 |

| 011910301205 | 2.5 | 36/0.3 | 7.41 | 0.7 | 1.1 | 13.1 X 6.2 | 30 |

| 011910300004 | 4 | 56/0.3 | 4.95 | 0.8 | 1.1 | 15.0 X 6.8 | 37 |

| 011910300006 | 6 | 84/0.3 | 3.30 | 0.8 | 1.2 | 17.2 X 7.7 | 46 |

| 011910300010 | 10 | 140/0.3 | 1.91 | 0.8 | 1.3 | 20.2 X 8.8 | 66 |

| 011910300016 | 16 | 126/0.4 | 1.21 | 0.8 | 1.4 | 23.6 X 10.0 | 85 |

| 011910300025 | 25 | 196/0.4 | 0.78 | 1.0 | 1.5 | 28.9 X 12.0 | 113 |

| 011910300035 | 35 | 276/0.4 | 0.554 | 1.0 | 1.6 | 32.7 X 13.4 | 139 |

| 011910300050 | 50 | 396/0.4 | 0.386 | 1.2 | 1.7 | 38.7 X 15.5 | 156 |

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required as per the list: 01 – With green/yellow earth core. We offer green/yellow earth core as our standard product. 02 – Without green/yellow earth core.

| Part Number | No. of Cores & Nominal Cross Sectional Area (Sq. mm) | Approx.Cable Diameter (mm) | Approx.Copper Weight (kg/km) | Approx.Cable Weight (kg/km) |

|---|---|---|---|---|

| 01200101xx16 | 2 x 1 | 9.5 | 18.3 | 162.9 |

| 01200102xx16 | 3 x 1 | 9.9 | 27.4 | 183.7 |

| 01200103xx16 | 4 x 1 | 10.5 | 36.5 | 212.8 |

| 01200104xx16 | 5 x 1 | 11.5 | 45.6 | 251.6 |

| 01200105xx16 | 2 x 1.5 | 10.0 | 26.7 | 187.9 |

| 01200106xx16 | 3 x 1.5 | 10.5 | 40.1 | 213.7 |

| 01200107xx16 | 4 x 1.5 | 11.4 | 53.5 | 256.3 |

| 01200108xx16 | 5 x 1.5 | 12.2 | 66.9 | 296.8 |

| 01200109xx16 | 2 x 2.5 | 11.5 | 44.6 | 252.6 |

| 01200110xx16 | 3 x 2.5 | 12.0 | 66.9 | 292.1 |

| 01200111xx16 | 4 x 2.5 | 12.9 | 89.2 | 347.2 |

| 01200112xx16 | 5 x 2.5 | 13.9 | 111.4 | 407.8 |

| 01200113xx16 | 2 x 4 | 12.9 | 71.9 | 334.0 |

| 01200114xx16 | 3 x 4 | 13.6 | 107.8 | 392.3 |

| 01200115xx16 | 4 x 4 | 14.6 | 143.8 | 470.9 |

| 01200116xx16 | 5 x 4 | 16.0 | 179.7 | 567.3 |

| 01200117xx16 | 6 x 2 | 14.2 | 107.8 | 420.7 |

| 01200118xx16 | 6 x 3 | 15.1 | 161.8 | 510.7 |

| 01200119xx16 | 6 x 4 | 16.3 | 215.7 | 619.4 |

| 01200120xx16 | 10 x 2 | 17.2 | 179.7 | 627.9 |

| 01200121xx16 | 10 x 3 | 18.3 | 269.6 | 769.9 |

| 01200122xx16 | 10 x 4 | 19.9 | 359.5 | 940.9 |

| 01200123xx16 | 16 x 2 | 19.7 | 287.6 | 862.2 |

| 01200124xx16 | 16 x 3 | 20.8 | 431.4 | 1059.4 |

| 01200125xx16 | 16 x 4 | 22.7 | 575.2 | 1311.0 |

| 01200126xx16 | 25 x 2 | 23.0 | 447.4 | 1218.8 |

| 01200127xx16 | 25 x 3 | 24.6 | 671.0 | 1531.3 |

| 01200128xx16 | 25 x 4 | 27.1 | 894.7 | 1923.2 |

| 01200129xx16 | 35 x 2 | 25.7 | 629.9 | 1585.0 |

| 01200130xx16 | 35 x 3 | 27.3 | 944.9 | 1990.7 |

| 01200131xx16 | 35 x 2 | 30.1 | 1259.9 | 2513.2 |

| 01200132xx16 | 50 x 2 | 30.3 | 903.8 | 2211.6 |

| 01200133xx16 | 50 x 3 | 32.2 | 1355.8 | 2789.8 |

| 01200134xx16 | 50 x 4 | 35.2 | 1807.7 | 3502.1 |

| 01200135xx16 | 70 x 2 | 34.1 | 1283.9 | 2923.8 |

| 01200136xx16 | 70 x 3 | 36.2 | 1925.8 | 3721.4 |

| 01200137xx16 | 70 x 4 | 39.7 | 2567.7 | 4695.7 |

| 01200138xx16 | 95 x 2 | 38.5 | 1711.8 | 3795.5 |

| 01200139xx16 | 95 x 3 | 41.0 | 2567.7 | 4853.0 |

| 01200140xx16 | 95 x 4 | 45.1 | 3423.6 | 6138.5 |

| 01200141xx16 | 120 x 2 | 41.8 | 2168.3 | 4603.2 |

| 01200142xx16 | 120 x 3 | 44.5 | 3252.5 | 5920.2 |

| 01200143xx16 | 120 x 4 | 49.0 | 4336.6 | 7513.4 |

| 01200144xx16 | 150 x 2 | 45.9 | 2674.7 | 5591.7 |

| 01200145xx16 | 150 x 3 | 48.9 | 4012.1 | 7211.7 |

| 01200146xx16 | 150 x 4 | 53.9 | 5349.4 | 9166.2 |

| 01200147xx16 | 185 x 2 | 50.6 | 3320.2 | 6848.6 |

| 01200148xx16 | 185 x 3 | 53.9 | 4980.3 | 8849.2 |

| 01200149xx16 | 185 x 4 | 59.5 | 6640.4 | 11267.5 |

| 01200150xx16 | 240 x 2 | 56.4 | 4279.6 | 8639.7 |

| 01200151xx16 | 240 x 3 | 60.2 | 6419.3 | 11207.5 |

| 01200152xx16 | 240 x 3 | 66.4 | 8559.1 | 14288.1 |