| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. CableDiameter (mm) | Approx. CopperWeight (kg/km) | Approx. CableWeight (kg/km) |

|---|---|---|---|---|

| 040200201075 | 2 x 0.75 | 7.4 | 30.3 | 80 |

| 040200311075 | 3G 0.75 | 7.9 | 38.5 | 95 |

| 040200301075 | 3 x 0.75 | 7.9 | 38.5 | 95 |

| 040200411075 | 4G 0.75 | 8.4 | 46.7 | 111 |

| 040200401075 | 4 x0.75 | 8.4 | 46.7 | 111 |

| 040200511075 | 5G 0.75 | 8.9 | 53.6 | 126 |

| 040200501075 | 5 x 0.75 | 8.9 | 53.6 | 126 |

| 040200711075 | 7G 0.75 | 9.7 | 70.4 | 156 |

| 040200701075 | 7 x 0.75 | 9.7 | 70.4 | 156 |

| 040201211075 | 12G 0.75 | 12.3 | 111.2 | 252 |

| 040201811075 | 18G 0.75 | 14.5 | 176.6 | 366 |

| 040202511075 | 25G 0.75 | 16.6 | 235.6 | 487 |

| 040203411075 | 34G 0.75 | 18.9 | 306.9 | 635 |

| 040204111075 | 41G 0.75 | 20.6 | 379.7 | 765 |

| 040200200001 | 2 x 1 | 7.9 | 35.3 | 92 |

| 040200310001 | 3G 1 | 8.2 | 46.5 | 107 |

| 040200300001 | 3 x 1 | 8.2 | 46.5 | 107 |

| 040200410001 | 4G 1 | 8.7 | 55.8 | 124 |

| 040200400001 | 4 x 1 | 8.7 | 55.8 | 124 |

| 040200510001 | 5G 1 | 9.5 | 67.4 | 149 |

| 040200710001 | 7G 1 | 10.2 | 87.5 | 182 |

| 040201210001 | 12G 1 | 13.3 | 160.8 | 318 |

| 040201810001 | 18G 1 | 15.5 | 222.7 | 437 |

| 040202510001 | 25G 1 | 17.5 | 298.6 | 574 |

| 040203410001 | 34G 1 | 20.2 | 389.4 | 760 |

| 040204110001 | 41G 1 | 22.0 | 480.8 | 915 |

| 040200201105 | 2 x 1.5 | 8.5 | 46.3 | 112 |

| 040200311105 | 3G 1.5 | 8.9 | 61.6 | 133 |

| 040200301105 | 3 x 1.5 | 8.9 | 61.6 | 133 |

| 040200411105 | 4G 1.5 | 9.6 | 76.0 | 159 |

| 040200401105 | 4 x 1.5 | 9.6 | 76.0 | 159 |

| 040200511105 | 5G 1.5 | 10.3 | 109.1 | 200 |

| 040200501105 | 5 x 1.5 | 10.3 | 109.1 | 200 |

| 040200711105 | 7G 1.5 | 11.3 | 137.0 | 246 |

| 040200701105 | 7 x 1.5 | 11.3 | 137.0 | 246 |

| 040201211105 | 12G 1.5 | 14.8 | 218.4 | 411 |

| 040201811105 | 18G 1.5 | 17.2 | 307.5 | 569 |

| 040202511105 | 25G 1.5 | 20.1 | 412.7 | 774 |

| 040203411105 | 34G 1.5 | 22.8 | 547.2 | 1014 |

| 040204111105 | 41G 1.5 | 24.7 | 673.1 | 1216 |

| 040200312105 | 3G 2.5 | 10.3 | 109.0 | 200 |

| 040200412105 | 4G 2.5 | 11.3 | 133.2 | 243 |

| 040200512105 | 5G 2.5 | 12.6 | 161.1 | 299 |

| 040200712105 | 7G 1.5 | 13.9 | 211.6 | 378 |

| 040201212105 | 12G 2.5 | 17.6 | 334.8 | 608 |

| 040200410004 | 4G 4 | 13.4 | 190.6 | 345 |

| 040200510004 | 5G 4 | 14.7 | 233.6 | 420 |

| 040200410006 | 4G 6 | 15.8 | 275.2 | 493 |

| 040200510006 | 5G 6 | 17.3 | 334.1 | 596 |

| 040200410010 | 4G 10 | 19.0 | 434.7 | 745 |

| 040200410016 | 4G 16 | 22.2 | 723.2 | 1130 |

For use as a data and control cable in machinery, computer systems etC as well as a signal cable for electronics. The high level of degree of interference protection. The screening density assures disturbance-free transmission of all signals and impulses. screening ensures a high. Such cables can also be used for outdoor applications for the permitted temperature range.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. CableDiameter (mm) | Approx. CopperWeight (kg/km) | Approx. CableWeight (kg/km) |

|---|---|---|---|---|

| 040300201050 | 2 x 0.5 | 5.8 | 19.3 | 45 |

| 040300311050 | 3G 0.5 | 6.1 | 25.5 | 56 |

| 040300301050 | 3 x 0.5 | 6.1 | 25.5 | 56 |

| 040300411050 | 4G 0.5 | 6.5 | 30.1 | 64 |

| 040300401050 | 4 x 0.5 | 6.5 | 30.1 | 64 |

| 040300511050 | 5G 0.5 | 7.0 | 35.8 | 75 |

| 040300501050 | 5 x 0.5 | 7.0 | 35.8 | 75 |

| 040300711050 | 7G 0.5 | 7.5 | 46.7 | 92 |

| 040300701050 | 7 x 0.5 | 7.5 | 46.7 | 92 |

| 040301211050 | 12G 0.5 | 9.9 | 74.2 | 152 |

| 040301201050 | 12 x 0.5 | 9.9 | 74.2 | 52 |

| 040301811050 | 18G 0.5 | 11.5 | 104.3 | 210 |

| 040301801050 | 18 x 0.5 | 11.5 | 104.3 | 210 |

| 040302511050 | 25G 0.5 | 13.4 | 140.0 | 278 |

| 040302501050 | 25 x 0.5 | 13.4 | 140.0 | 278 |

| 040300201075 | 2 x 0.75 | 6.2 | 25.7 | 54 |

| 040300311075 | 3G 0.75 | 6.5 | 32.3 | 65 |

| 040300301075 | 3 x 0.75 | 6.5 | 32.3 | 65 |

| 040300411075 | 4G 0.75 | 7.0 | 40.4 | 78 |

| 040300401075 | 4 x 0.75 | 7.0 | 40.4 | 78 |

| 040300511075 | 5G 0.75 | 7.7 | 48.9 | 95 |

| 040300501075 | 5 x 0.75 | 7.7 | 48.9 | 95 |

| 040300711075 | 7G 0.75 | 8.3 | 64.5 | 119 |

| 040300701075 | 7 x 0.75 | 8.3 | 64.5 | 119 |

| 040301211075 | 12G 0.75 | 10.9 | 103.2 | 194 |

| 040301811075 | 18G 0.75 | 12.7 | 147.4 | 271 |

| 040302511075 | 25G 0.75 | 14.8 | 219.5 | 372 |

| 040302501075 | 25 x 0.75 | 14.8 | 219.5 | 372 |

| 040300200001 | 2 x 1 | 6.5 | 30.5 | 61 |

| 040300310001 | 3G 1 | 6.8 | 40.3 | 75 |

| 040300300001 | 3 x 1 | 6.8 | 40.3 | 75 |

| 040300410001 | 4G 1 | 7.3 | 51.0 | 91 |

| 040300400001 | 4 x 1 | 7.3 | 51.0 | 91 |

| 040300510001 | 5G 1 | 8.1 | 60.7 | 110 |

| 040300500001 | 5 x 1 | 8.1 | 60.7 | 110 |

| 040300710001 | 7G 1 | 8.8 | 80.5 | 140 |

| 040300700001 | 7 x 1 | 8.8 | 80.5 | 140 |

| 040301210001 | 12G 1 | 11.5 | 131.2 | 229 |

| 040301810001 | 18G 1 | 13.9 | 188.5 | 337 |

| 040302510001 | 25G 1 | 15.9 | 277.9 | 452 |

| 040300201105 | 2 x 1.5 | 7.1 | 40.8 | 75 |

| 040300311105 | 3G 1.5 | 7.5 | 53.8 | 95 |

| 040300301105 | 3 x 1.5 | 7.5 | 53.8 | 95 |

| 040300411105 | 4G 1.5 | 8.2 | 69.0 | 119 |

| 040300401105 | 4 x 1.5 | 8.2 | 69.0 | 119 |

| 040300511105 | 5G 1.5 | 8.9 | 84.4 | 142 |

| 040300501105 | 5 x 1.5 | 8.9 | 84.4 | 142 |

| 040300711105 | 7G 1.5 | 9.9 | 112.9 | 187 |

| 040300701105 | 7 x 1.5 | 9.9 | 112.9 | 187 |

| 040301211105 | 12G 1.5 | 13.0 | 183.5 | 306 |

| 040301811105 | 18G 1.5 | 15.6 | 288.5 | 463 |

| 040302511105 | 25G 1.5 | 17.9 | 395.0 | 614 |

| 040303411105 | 34G 1.5 | 20.8 | 511.9 | 811 |

| 040300311205 | 3G 2.5 | 8.9 | 84.4 | 140 |

| 040300411205 | 4G 2.5 | 9.9 | 107.5 | 179 |

| 040300511205 | 5G 2.5 | 11.0 | 130.8 | 219 |

| 040300711205 | 7G 2.5 | 11.9 | 176.5 | 281 |

| 040301211205 | 12G 2.5 | 16.0 | 314.8 | 491 |

| 040301811205 | 18G 2.5 | 19.0 | 454.1 | 709 |

| 040302511205 | 25G 2.5 | 22.2 | 617.0 | 954 |

| 040300410004 | 4G 4 | 11.6 | 160.8 | 258 |

| 040300710004 | 7G 4 | 14.4 | 269.0 | 425 |

| 040300410006 | 4G 6 | 14.2 | 233.7 | 382 |

| 040300710006 | 7G 6 | 17.0 | 415.7 | 619 |

| 040300410010 | 4G 10 | 17.2 | 402.9 | 608 |

| 040300510010 | 5G 10 | 19.5 | 499.3 | 772 |

| 040300410016 | 4G 16 | 20.2 | 647.6 | 909 |

| 040300510016 | 5G 16 | 22.6 | 799.6 | 1132 |

| 040300410025 | 4G 25 | 25.1 | 986.2 | 1396 |

| 040300510025 | 5G 25 | 28.0 | 1220.9 | 1737 |

| 040300410035 | 4G 35 | 28.0 | 1369.0 | 1838 |

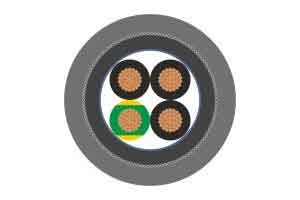

These cables are suitable for Machine tools, industrial machinery, measurement control, and electrical applications Very suitable for oily wet areas withing machinery and production shop floor that are subject to normal mechanical stress Resistant to contact with mineral oilbased lubricants, diluted acids, aqueous alkaline solutions and other chemical media Outdoor use is possible within the indicated temperature range.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. CableDiameter (mm) | Approx. CopperWeight (kg/km) | Approx. CableWeight (kg/km) |

|---|---|---|---|---|

| 040400201050 | 2 x 0.5 | 5.9 | 8.7 | 39 |

| 040400311050 | 3G 0.5 | 6.2 | 13.0 | 45 |

| 040400411050 | 4G 0.5 | 6.9 | 17.4 | 57 |

| 040400511050 | 5G 0.5 | 7.4 | 21.7 | 67 |

| 040400711050 | 7G 0.5 | 9.1 | 30.4 | 100 |

| 040401211050 | 12G 0.5 | 11.3 | 52.2 | 158 |

| 040401811050 | 18G 0.5 | 13.2 | 78.2 | 220 |

| 040402511050 | 25G 0.5 | 15.0 | 108.6 | 290 |

| 040400201075 | 2 x 0.75 | 6.4 | 13.0 | 48 |

| 040400311075 | 3G 0.75 | 6.8 | 19.6 | 58 |

| 040400411075 | 4G 0.75 | 7.4 | 26.1 | 71 |

| 040400511075 | 5G 0.75 | 8.6 | 32.6 | 94 |

| 040400711075 | 7G 0.75 | 10.0 | 45.6 | 128 |

| 040401211075 | 12G 0.75 | 12.4 | 78.2 | 203 |

| 040401811075 | 18G 0.75 | 14.4 | 117.3 | 283 |

| 040402511075 | 25G 0.75 | 17.2 | 163.0 | 401 |

| 040400200001 | 2 x 1 | 6.8 | 17.4 | 57 |

| 040400310001 | 3G 1 | 7.2 | 26.1 | 69 |

| 040400410001 | 4G 1 | 8.2 | 34.8 | 90 |

| 040400510001 | 5G 1 | 9.0 | 43.5 | 110 |

| 040400710001 | 7G 1 | 11.1 | 60.8 | 163 |

| 040401210001 | 12G 1 | 13.2 | 104.3 | 244 |

| 040401810001 | 18G 1 | 15.4 | 156.5 | 344 |

| 040402510001 | 25G 1 | 19.0 | 217.3 | 507 |

| 040403410001 | 34G 1 | 21.8 | 295.5 | 675 |

| 040404110001 | 41G 1 | 23.4 | 356.4 | 791 |

| 040400201105 | 2 x 1.5 | 7.4 | 25.5 | 71 |

| 040400311105 | 3G 1.5 | 8.3 | 38.2 | 94 |

| 040400411105 | 4G 1.5 | 9.0 | 50.9 | 116 |

| 040400511105 | 5G 1.5 | 9.8 | 63.7 | 140 |

| 040400711105 | 7G 1.5 | 12.2 | 89.1 | 209 |

| 040401211105 | 12G 1.5 | 14.5 | 152.8 | 317 |

| 040401811105 | 18G 1.5 | 17.6 | 229.2 | 471 |

| 040402511105 | 25G 1.5 | 20.7 | 318.3 | 653 |

| 040404111105 | 41G 1.5 | 26.3 | 522.0 | 1060 |

| 040400311205 | 3G 2.5 | 9.7 | 63.7 | 139 |

| 040400411205 | 4G 2.5 | 11.0 | 84.9 | 181 |

| 040400511205 | 5G 2.5 | 12.1 | 106.1 | 221 |

| 040400711205 | 7G 2.5 | 14.2 | 148.5 | 307 |

| 040401211205 | 12G 2.5 | 17.8 | 254.6 | 500 |

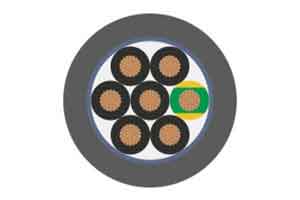

For use as a data and control cable in machinery, computer systems etC as well as a signal cable for electronics. The high level of screening ensures a high degree of interference protection. The screening density assures disturbance-free transmission of all signals and impulses. Such cables can also be used for outdoor applications for the permitted temperature range.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040500311050 | 3G 0.5 | 8.3 | 31.1 | 83 |

| 040500411050 | 4G 0.5 | 8.8 | 37.1 | 95 |

| 040500511050 | 5G 0.5 | 9.7 | 43.3 | 114 |

| 040500711050 | 7G 0.5 | 11.2 | 53.8 | 150 |

| 040501211050 | 12G 0.5 | 13.7 | 83.1 | 226 |

| 040501811050 | 18G 0.5 | 15.7 | 114.4 | 301 |

| 040502511050 | 25G 0.5 | 18.5 | 176.0 | 430 |

| 040500201075 | 2 x 0.75 | 8.4 | 31.0 | 84 |

| 040500311075 | 3G 0.75 | 8.7 | 38.8 | 95 |

| 040500411075 | 4G 0.75 | 9.5 | 47.0 | 114 |

| 040500511075 | 5G 0.75 | 10.2 | 55.4 | 133 |

| 040500711075 | 7G 0.75 | 11.9 | 71.2 | 179 |

| 040501211075 | 12G 0.75 | 14.5 | 111.8 | 269 |

| 040502511075 | 25G 0.75 | 20.3 | 236.3 | 542 |

| 040500200001 | 2 x 1 | 8.7 | 36.2 | 93 |

| 040500310001 | 3G 1 | 9.3 | 46.3 | 111 |

| 040500410001 | 4G 1 | 9.9 | 58.3 | 131 |

| 040500510001 | 5G 1 | 10.8 | 67.6 | 154 |

| 040500710001 | 7G 1 | 12.8 | 88.2 | 213 |

| 040501210001 | 12G 1 | 15.4 | 161.2 | 332 |

| 040501810001 | 18G 1 | 17.7 | 223.2 | 448 |

| 040502510001 | 25G 1 | 21.5 | 295.9 | 637 |

| 040503410001 | 34G 1 | 23.8 | 386.0 | 799 |

| 040500201105 | 2 x 1.5 | 9.5 | 46.8 | 114 |

| 040500311105 | 3G 1.5 | 9.9 | 60.8 | 132 |

| 040500411105 | 4G 1.5 | 10.8 | 76.3 | 161 |

| 040500511105 | 5G 1.5 | 11.32 | 91.0 | 182 |

| 040500711105 | 7G 1.5 | 13.92 | 119.5 | 265 |

| 040501211105 | 12G 1.5 | 16.8 | 216.1 | 416 |

| 040501811105 | 18G 1.5 | 20 | 302.9 | 591 |

| 040502511105 | 25G 1.5 | 23.5 | 408.1 | 808 |

| 040504111105 | 41G 1.5 | 28.72 | 635.4 | 1229 |

| 040500311205 | 3G 2.5 | 11.12 | 90.9 | 178 |

| 040500411205 | 4G 2.5 | 12.32 | 115.1 | 222 |

| 040500511205 | 5G 2.5 | 14 | 159.9 | 296 |

| 040500711205 | 7G 1.5 | 16.4 | 208.5 | 402 |

| 040501211205 | 12G 2.5 | 21 | 329.4 | 648 |

Connecting cable between frequency convertor and motor. Connecting cable between servo controller and motor plant engineering. Combined power and control cable for motors with Variable frequency drives. Once common cable for multiple circuits.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040601010113 | 4 G 0.75 + 2 x (2 x 0.34) | 9.5 | 59.9 | 124 |

| 040601020113 | 4 G 1.5 + 2 x (2 x 0.75) | 12.1 | 103.0 | 195 |

| 040601030113 | 4 G 2.5 + (2 x 2 x 0.75) | 13.9 | 127.6 | 258 |

| 040601040113 | 4 G 4 + (2 x 0.75 + 2 x 1) | 15.8 | 182.8 | 351 |

| 040601050113 | 4 G 6 + (2 x 0.75 + 2 x 1) | 16.7 | 250.3 | 435 |

| 040601060113 | 4 G 16 + (2 x 2 x 1) | 23.5 | 626.3 | 1052 |

| 040601070113 | 4 G 1.5 +(2 x 0.75) | 11.7 | 76.9 | 174 |

| 040601080113 | 5 G 1.5 +(2 x 0.75) | 12.7 | 89.7 | 203 |

| 040601090113 | 7 G 1.5 +(2 x 0.75) | 12.4 | 115.1 | 203 |

| 040601100113 | 4 G 2.5 +(2 x 0.75) | 13.1 | 110.9 | 239 |

| 040601110113 | 7 G 2.5 +(2 x 0.75) | 15.2 | 174.6 | 335 |

Connecting cable between frequency convertor and motor. Connecting cable between servo controller and motor plant engineering. Combined power and control cable for motors with Variable frequency drives. Once common cable for multiple circuits.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040601010113 | 4 G 0.75 + 2 x (2 x 0.34) | 9.5 | 59.9 | 124 |

| 040601020113 | 4 G 1.5 + 2 x (2 x 0.75) | 12.1 | 103.0 | 195 |

| 040601030113 | 4 G 2.5 + (2 x 2 x 0.75) | 13.9 | 127.6 | 258 |

| 040601040113 | 4 G 4 + (2 x 0.75 + 2 x 1) | 15.8 | 182.8 | 351 |

| 040601050113 | 4 G 6 + (2 x 0.75 + 2 x 1) | 16.7 | 250.3 | 435 |

| 040601060113 | 4 G 16 + (2 x 2 x 1) | 23.5 | 626.3 | 1052 |

| 040601070113 | 4 G 1.5 +(2 x 0.75) | 11.7 | 76.9 | 174 |

| 040601080113 | 5 G 1.5 +(2 x 0.75) | 12.7 | 89.7 | 203 |

| 040601090113 | 7 G 1.5 +(2 x 0.75) | 12.4 | 115.1 | 203 |

| 040601100113 | 4 G 2.5 +(2 x 0.75) | 13.1 | 110.9 | 239 |

| 040601110113 | 7 G 2.5 +(2 x 0.75) | 15.2 | 174.6 | 335 |

Connecting cable between frequency convertor and motor. This motor power supply cable is used for the frequency converters and assures electromagnetic compatibility in plants and buildings Handling equipment, for SIMOVERT drives, they are particularly suitable for use with industrial pumps,Ventilators, conveyor belts and air-conditioning installations and similar applications.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040801010116 | 4 G 1.5 | 11.4 | 72.9 | 167 |

| 040801020116 | 4 G 2.5 | 12.4 | 110.0 | 215 |

| 040801030116 | 4 G 4.0 | 15.6 | 193.3 | 363 |

| 040801040116 | 4 G 6.0 | 17.0 | 269.0 | 462 |

| 040801050116 | 4 G 10.0 | 19.6 | 435.0 | 660 |

| 040801060116 | 4 G 16.0 | 22.1 | 698.3 | 955 |

| 040801070116 | 4 G 25.0 | 26.3 | 1045.7 | 1390 |

| 040801080116 | 4 G 35.0 | 29.5 | 1431.6 | 1842 |

| 040801090116 | 4 G 50.0 | 35.8 | 2010.3 | 2656 |

| 040801100116 | 4 G 70.0 | 40.3 | 2784.5 | 3579 |

| 040801110116 | 4 G 95.0 | 46.5 | 3146.1 | 4371 |

| 040801120116 | 4 G 120.0 | 53.2 | 4687.6 | 6190 |

| 040801130116 | 4 G 150.0 | 57.3 | 5643.8 | 7315 |

| 040801140116 | 4 G 185.0 | 62.3 | 6959.5 | 8853 |

| 040801150116 | 3 x 1.5 + 3 G 0.25 | 11.4 | 65.1 | 158 |

| 040801160116 | 3 x 2.5 + 3 G 0.5 | 12.2 | 99.4 | 202 |

| 040801170116 | 3 x 4 + 3 G 0.75 | 14.4 | 174.0 | 308 |

| 040801180116 | 3 x 6 + 3 G 1 | 15.7 | 237.6 | 391 |

| 040801190116 | 3 x 10 + 3 G 1.5 | 18.0 | 375.2 | 554 |

| 040801200116 | 3 x 16 + 3 G 2.5 | 20.2 | 603.9 | 809 |

| 040801210116 | 3 x 25 + 3 G 4 | 23.8 | 906.3 | 1174 |

| 040801220116 | 3 x 35 + 3 G 6 | 26.9 | 1250.8 | 1581 |

| 040801230116 | 3 x 50 + 3 G 10 | 32.6 | 1798.9 | 2317 |

| 040801240116 | 3 x 70 + 3 G 10 | 36.4 | 2380.3 | 2988 |

| 040801250116 | 3 x 95 + 3 G 16 | 42.0 | 2825.8 | 3730 |

| 040801260116 | 3 x 120 + 3 G 16 | 47.8 | 3991.9 | 5072 |

| 040801270116 | 3 x 150 + 3 G 25 | 51.6 | 4946.4 | 6193 |

| 040801280116 | 3 x 185 + 3 G 35 | 56.5 | 6217.8 | 7691 |

Connecting between the frequency convertor and the motor for power circuits in machine cabling. In dry damp or wet interiors with normal mechanical stress conditions. For outdoor usage within the permitted range of temperature.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040801010116 | 4 G 1.5 | 11.4 | 72.9 | 167 |

| 040801020116 | 4 G 2.5 | 12.4 | 110.0 | 215 |

| 040801030116 | 4 G 4.0 | 15.6 | 193.3 | 363 |

| 040801040116 | 4 G 6.0 | 17.0 | 269.0 | 462 |

| 040801050116 | 4 G 10.0 | 19.6 | 435.0 | 660 |

| 040801060116 | 4 G 16.0 | 22.1 | 698.3 | 955 |

| 040801070116 | 4 G 25.0 | 26.3 | 1045.7 | 1390 |

| 040801080116 | 4 G 35.0 | 29.5 | 1431.6 | 1842 |

| 040801090116 | 4 G 50.0 | 35.8 | 2010.3 | 2656 |

| 040801100116 | 4 G 70.0 | 40.3 | 2784.5 | 3579 |

| 040801110116 | 4 G 95.0 | 46.5 | 3146.1 | 4371 |

| 040801120116 | 4 G 120.0 | 53.2 | 4687.6 | 6190 |

| 040801130116 | 4 G 150.0 | 57.3 | 5643.8 | 7315 |

| 040801140116 | 4 G 185.0 | 62.3 | 6959.5 | 8853 |

| 040801150116 | 3 x 1.5 + 3 G 0.25 | 11.4 | 65.1 | 158 |

| 040801160116 | 3 x 2.5 + 3 G 0.5 | 12.2 | 99.4 | 202 |

| 040801170116 | 3 x 4 + 3 G 0.75 | 14.4 | 174.0 | 308 |

| 040801180116 | 3 x 6 + 3 G 1 | 15.7 | 237.6 | 391 |

| 040801190116 | 3 x 10 + 3 G 1.5 | 18.0 | 375.2 | 554 |

| 040801200116 | 3 x 16 + 3 G 2.5 | 20.2 | 603.9 | 809 |

| 040801210116 | 3 x 25 + 3 G 4 | 23.8 | 906.3 | 1174 |

| 040801220116 | 3 x 35 + 3 G 6 | 26.9 | 1250.8 | 1581 |

| 040801230116 | 3 x 50 + 3 G 10 | 32.6 | 1798.9 | 2317 |

| 040801240116 | 3 x 70 + 3 G 10 | 36.4 | 2380.3 | 2988 |

| 040801250116 | 3 x 95 + 3 G 16 | 42.0 | 2825.8 | 3730 |

| 040801260116 | 3 x 120 + 3 G 16 | 47.8 | 3991.9 | 5072 |

| 040801270116 | 3 x 150 + 3 G 25 | 51.6 | 4946.4 | 6193 |

| 040801280116 | 3 x 185 + 3 G 35 | 56.5 | 6217.8 | 7691 |

Connecting between the frequency convertor and the motor for power circuits in machine cabling. In dry damp or wet interiors with normal mechanical stress conditions. For outdoor usage within the permitted range of temperature.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041000411105 | 4G 1.5 | 9.8 | 74.3 | 130 |

| 041000411205 | 4G 2.5 | 11.9 | 113.8 | 205 |

| 041000410004 | 4G 4 | 13.5 | 169.7 | 286 |

| 041000410010 | 4G 10 | 19.7 | 428.0 | 641 |

| 041000410016 | 4G 16 | 23.9 | 661.4 | 931 |

| 041000410035 | 4G 35 | 33.3 | 1386.2 | 1808 |

| 041000410050 | 4G 50 | 38.3 | 1937.2 | 2476 |

Connecting between the frequency convertor and the motor for power circuits in machine cabling. In dry damp or wet interiors with normal mechanical stress conditions. For outdoor usage within the permitted range of temperature.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041100411105 | 4G1.5 | 10.0 | 1.5 | 132 |

| 041100411205 | 4G2.5 | 11.9 | 2.5 | 189 |

| 041100410004 | 4G4 | 13.7 | 4 | 268 |

| 041100410006 | 4G6 | 15.1 | 6 | 374 |

| 041100410010 | 4G10 | 19.6 | 10 | 609 |

| 041100410016 | 4G16 | 22.8 | 16 | 896 |

| 041100511105 | 5G1.5 | 11.2 | 1.5 | 161 |

| 041100511205 | 5G2.5 | 13.3 | 2.5 | 233 |

| 041100510004 | 5G4 | 15.2 | 4 | 330 |

| 041100510006 | 5G6 | 16.8 | 6 | 461 |

| 041100510016 | 5G16 | 25.5 | 16 | 1106 |

| 041100510025 | 5G25 | 30.8 | 25 | 1699 |

For use in power chains or moving machine parts. Suitable for use in measuring, control and regulating circuits. Power circuits for electrical equipment used in automation engineering assembly lines, production lines and in all kinds of machines and plant engineering.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041200201050 | 2 x 0.5 | 5.3 | 8.7 | 39 |

| 041200311050 | 3G 0.5 | 5.7 | 13.0 | 48 |

| 041200411050 | 4G 0.5 | 6.3 | 17.4 | 60 |

| 041200511050 | 5G 0.5 | 6.8 | 21.7 | 71 |

| 041200711050 | 7G 0.5 | 8.0 | 30.4 | 99 |

| 041201211050 | 12G 0.5 | 9.5 | 52.1 | 147 |

| 041201811050 | 18G 0.5 | 11.4 | 78.1 | 214 |

| 041202511050 | 25G 0.5 | 13.7 | 108.5 | 306 |

| 041203011050 | 30G 0.5 | 14.3 | 130.2 | 344 |

| 041203411050 | 34G 0.5 | 15.6 | 147.5 | 403 |

| 041205011050 | 50G 0.5 | 18.5 | 216.9 | 574 |

| 041200201075 | 2 x 0.75 | 5.7 | 13.0 | 48 |

| 041200311075 | 3G 0.75 | 6.2 | 19.5 | 60 |

| 041200411075 | 4G 0.75 | 6.8 | 6.0 | 75 |

| 041200511075 | 5G 0.75 | 7.4 | 2.5 | 90 |

| 041200711075 | 7G 0.75 | 8.9 | 5.6 | 129 |

| 041201211075 | 12G 0.75 | 10.6 | 78.1 | 194 |

| 041201611075 | 16G 0.75 | 12.0 | 104.1 | 253 |

| 041201811075 | 18G 0.75 | 12.7 | 117.2 | 283 |

| 041202511075 | 25G 0.75 | 15.2 | 162.7 | 402 |

| 041200200001 | 2 x 1 | 6.1 | 17.4 | 57 |

| 041200310001 | 3G 1 | 6.6 | 26.0 | 72 |

| 041200410001 | 4G 1 | 7.3 | 34.7 | 90 |

| 041200510001 | 5G 1 | 8.0 | 43.4 | 110 |

| 041200710001 | 7G 1 | 9.6 | 60.7 | 157 |

| 041201210001 | 12G 1 | 11.4 | 104.1 | 237 |

| 041201410001 | 14G 1 | 12.3 | 121.5 | 276 |

| 041201610001 | 16G 1 | 13.0 | 138.8 | 311 |

| 041201810001 | 18G 1 | 13.9 | 156.2 | 353 |

| 041202510001 | 25G 1 | 16.4 | 216.9 | 491 |

| 041202610001 | 26G 1 | 16.4 | 225.6 | 498 |

| 041203410001 | 34G 1 | 18.9 | 295.1 | 658 |

| 041204110001 | 41G 1 | 20.6 | 355.8 | 786 |

| 041205010001 | 50G 1 | 22.3 | 433.9 | 936 |

| 041206510001 | 65G 1 | 25.4 | 564.1 | 1215 |

| 041200201105 | 2 x 1.5 | 6.8 | 26.0 | 75 |

| 041200311105 | 3G 1.5 | 7.4 | 39.1 | 96 |

| 041200411105 | 4G 1.5 | 8.1 | 52.1 | 119 |

| 041200511105 | 5G 1.5 | 9.1 | 65.1 | 150 |

| 041200711105 | 7G 1.5 | 9.9 | 91.1 | 189 |

| 041201211105 | 12G 1.5 | 12.9 | 156.2 | 322 |

| 041201811105 | 18G 1.5 | 15.0 | 234.3 | 456 |

| 041202511105 | 25G 1.5 | 17.6 | 325.4 | 630 |

| 041202611105 | 26G 1.5 | 17.8 | 338.4 | 649 |

| 041203411105 | 34G 1.5 | 20.2 | 442.6 | 841 |

| 041204111105 | 41G 1.5 | 22.0 | 533.7 | 1006 |

| 041204211105 | 42G 1.5 | 22.0 | 546.7 | 1017 |

| 041205011105 | 50G 1.5 | 24.0 | 650.8 | 1210 |

| 041200311205 | 3G 2.5 | 9.0 | 65.1 | 148 |

| 041200411205 | 4G 2.5 | 10.0 | 86.8 | 188 |

| 041200511205 | 5G 2.5 | 11.2 | 108.5 | 235 |

| 041200711205 | 7G 2.5 | 12.5 | 151.9 | 307 |

| 041201211205 | 12G 2.5 | 16.0 | 260.3 | 513 |

| 041201411205 | 14G 2.5 | 17.2 | 303.7 | 595 |

| 041200310004 | 3G 4 | 10.6 | 104.1 | 217 |

| 041200410004 | 4G 4 | 11.7 | 138.8 | 274 |

| 041200510004 | 5G 4 | 13.1 | 173.6 | 343 |

| 041200410006 | 4G 6 | 13.9 | 208.6 | 398 |

| 041200510006 | 5G 6 | 15.5 | 260.8 | 496 |

| 041200410010 | 4G 10 | 17.6 | 358.5 | 658 |

| 041200510010 | 5G 10 | 19.6 | 448.2 | 819 |

| 041200410016 | 4G 16 | 21.0 | 565.0 | 983 |

| 041200510016 | 5G 16 | 23.6 | 706.2 | 1236 |

For use in power chains or moving machine parts. Suitable for use in measuring, control and regulating circuits. Power circuits for electrical equipment used in automation engineering assembly lines, production lines and in all kinds of machines and plant engineering.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041300201050 | 2 x 0.5 | 7.2 | 24.5 | 76 |

| 041300311050 | 3G 0.5 | 7.5 | 30.2 | 86 |

| 041300411050 | 4G 0.5 | 8.1 | 36.3 | 102 |

| 041300511050 | 5G 0.5 | 8.6 | 42.4 | 116 |

| 041300711050 | 7G 0.5 | 9.1 | 54.3 | 136 |

| 041301211050 | 12G 0.5 | 11.5 | 84.2 | 216 |

| 041301811050 | 18G 0.5 | 13.5 | 117.5 | 301 |

| 041302511050 | 25G 0.5 | 15.12 | 156.9 | 386 |

| 041303011050 | 30G 0.5 | 16.02 | 185.1 | 442 |

| 041300201075 | 2 x 0.75 | 7.6 | 30.6 | 88 |

| 041300311075 | 3G 0.75 | 8.1 | 39.5 | 104 |

| 041300411075 | 4G 0.75 | 8.6 | 47.2 | 120 |

| 041300511075 | 5G 0.75 | 9.1 | 56.6 | 138 |

| 041300711075 | 7G 0.75 | 9.9 | 71.7 | 167 |

| 041301211075 | 12G 0.75 | 12.5 | 117.1 | 271 |

| 041301811075 | 18G 0.75 | 14.42 | 166.1 | 371 |

| 041302511075 | 25G 0.75 | 16.52 | 221.4 | 491 |

| 041303011075 | 30G 0.75 | 18 | 288.2 | 595 |

| 041300200001 | 2 x 1 | 8.1 | 37.3 | 102 |

| 041300310001 | 3G 1 | 8.4 | 47.3 | 116 |

| 041300410001 | 4G 1 | 8.9 | 58.8 | 136 |

| 041300510001 | 5G 1 | 9.7 | 69.4 | 161 |

| 041301210001 | 12G 1 | 13.22 | 145.7 | 316 |

| 041301810001 | 18G 1 | 15.42 | 210.4 | 442 |

| 041302510001 | 25G 1 | 17.4 | 286.0 | 580 |

| 041302610001 | 26G 1 | 17.4 | 295.7 | 588 |

| 041303410001 | 34G 1 | 20.2 | 392.5 | 788 |

| 041304110001 | 41G 1 | 22 | 466.3 | 927 |

| 041305010001 | 50G 1 | 23.7 | 554.0 | 1093 |

| 041300201105 | 2 x 1.5 | 8.9 | 48.2 | 126 |

| 041300311105 | 3G 1.5 | 9.3 | 64.0 | 148 |

| 041300411105 | 4G 1.5 | 10.0 | 82.3 | 180 |

| 041300511105 | 5G 1.5 | 10.5 | 96.8 | 202 |

| 041300711105 | 7G 1.5 | 11.5 | 128.8 | 254 |

| 041301211105 | 12G 1.5 | 15.2 | 216.8 | 439 |

| 041301611105 | 16G 1.5 | 16.7 | 295.2 | 555 |

| 041301811105 | 18G 1.5 | 17.7 | 317.5 | 617 |

| 041302511105 | 25G 1.5 | 20.7 | 426.7 | 840 |

| 041303411105 | 34G 1.5 | 23.5 | 563.9 | 1095 |

| 041300311205 | 3G 2.5 | 10.3 | 100.7 | 200 |

| 041300411205 | 4G 2.5 | 11.3 | 129.4 | 249 |

| 041300511205 | 5G 2.5 | 12.6 | 158.5 | 309 |

| 041300711205 | 7G 2.5 | 13.9 | 211.5 | 392 |

| 041300410004 | 4G 4 | 13.4 | 192.3 | 361 |

| 041300510004 | 5G 4 | 14.7 | 236.4 | 439 |

| 041300410006 | 4G 6 | 15.8 | 254.9 | 492 |

| 041300410010 | 4G 10 | 19.3 | 414.4 | 763 |

| 041300410016 | 4G 16 | 22.0 | 635.7 | 1076 |

For use in power chains or moving machine parts. Suitable for use in measuring, control and regulating circuits. Power circuits for electrical equipment used in automation engineering assembly lines, production lines and in all kinds of machines and plant engineering.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041300201050 | 2 x 0.5 | 7.2 | 24.5 | 76 |

| 041300311050 | 3G 0.5 | 7.5 | 30.2 | 86 |

| 041300411050 | 4G 0.5 | 8.1 | 36.3 | 102 |

| 041300511050 | 5G 0.5 | 8.6 | 42.4 | 116 |

| 041300711050 | 7G 0.5 | 9.1 | 54.3 | 136 |

| 041301211050 | 12G 0.5 | 11.5 | 84.2 | 216 |

| 041301811050 | 18G 0.5 | 13.5 | 117.5 | 301 |

| 041302511050 | 25G 0.5 | 15.12 | 156.9 | 386 |

| 041303011050 | 30G 0.5 | 16.02 | 185.1 | 442 |

| 041300201075 | 2 x 0.75 | 7.6 | 30.6 | 88 |

| 041300311075 | 3G 0.75 | 8.1 | 39.5 | 104 |

| 041300411075 | 4G 0.75 | 8.6 | 47.2 | 120 |

| 041300511075 | 5G 0.75 | 9.1 | 56.6 | 138 |

| 041300711075 | 7G 0.75 | 9.9 | 71.7 | 167 |

| 041301211075 | 12G 0.75 | 12.5 | 117.1 | 271 |

| 041301811075 | 18G 0.75 | 14.42 | 166.1 | 371 |

| 041302511075 | 25G 0.75 | 16.52 | 221.4 | 491 |

| 041303011075 | 30G 0.75 | 18 | 288.2 | 595 |

| 041300200001 | 2 x 1 | 8.1 | 37.3 | 102 |

| 041300310001 | 3G 1 | 8.4 | 47.3 | 116 |

| 041300410001 | 4G 1 | 8.9 | 58.8 | 136 |

| 041300510001 | 5G 1 | 9.7 | 69.4 | 161 |

| 041301210001 | 12G 1 | 13.22 | 145.7 | 316 |

| 041301810001 | 18G 1 | 15.42 | 210.4 | 442 |

| 041302510001 | 25G 1 | 17.4 | 286.0 | 580 |

| 041302610001 | 26G 1 | 17.4 | 295.7 | 588 |

| 041303410001 | 34G 1 | 20.2 | 392.5 | 788 |

| 041304110001 | 41G 1 | 22 | 466.3 | 927 |

| 041305010001 | 50G 1 | 23.7 | 554.0 | 1093 |

| 041300201105 | 2 x 1.5 | 8.9 | 48.2 | 126 |

| 041300311105 | 3G 1.5 | 9.3 | 64.0 | 148 |

| 041300411105 | 4G 1.5 | 10.0 | 82.3 | 180 |

| 041300511105 | 5G 1.5 | 10.5 | 96.8 | 202 |

| 041300711105 | 7G 1.5 | 11.5 | 128.8 | 254 |

| 041301211105 | 12G 1.5 | 15.2 | 216.8 | 439 |

| 041301611105 | 16G 1.5 | 16.7 | 295.2 | 555 |

| 041301811105 | 18G 1.5 | 17.7 | 317.5 | 617 |

| 041302511105 | 25G 1.5 | 20.7 | 426.7 | 840 |

| 041303411105 | 34G 1.5 | 23.5 | 563.9 | 1095 |

| 041300311205 | 3G 2.5 | 10.3 | 100.7 | 200 |

| 041300411205 | 4G 2.5 | 11.3 | 129.4 | 249 |

| 041300511205 | 5G 2.5 | 12.6 | 158.5 | 309 |

| 041300711205 | 7G 2.5 | 13.9 | 211.5 | 392 |

| 041300410004 | 4G 4 | 13.4 | 192.3 | 361 |

| 041300510004 | 5G 4 | 14.7 | 236.4 | 439 |

| 041300410006 | 4G 6 | 15.8 | 254.9 | 492 |

| 041300410010 | 4G 10 | 19.3 | 414.4 | 763 |

| 041300410016 | 4G 16 | 22.0 | 635.7 | 1076 |

Connecting between the frequency convertor and the motor for power circuits in machine cabling. In dry damp or wet interiors with normal mechanical stress conditions. For outdoor usage within the permitted range of temperature.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041500201050 | 2 x 0.5 | 7.2 | 24.5 | 72 |

| 041500311050 | 3G 0.5 | 7.5 | 30.2 | 81 |

| 041500411050 | 4G 0.5 | 8.1 | 36.3 | 96 |

| 041500511050 | 5G 0.5 | 8.6 | 42.4 | 110 |

| 041500711050 | 7G 0.5 | 9.1 | 54.3 | 130 |

| 041501211050 | 12G 0.5 | 11.5 | 84.2 | 207 |

| 041500201075 | 2 x 0.75 | 7.6 | 30.6 | 83 |

| 041500311075 | 3G 0.75 | 8.1 | 39.5 | 99 |

| 041500411075 | 4G 0.75 | 8.6 | 47.2 | 114 |

| 041500511075 | 5G 0.75 | 9.1 | 56.6 | 132 |

| 041500711075 | 7G 0.75 | 9.9 | 71.7 | 160 |

| 041501211075 | 12G 0.75 | 12.5 | 117.1 | 261 |

| 041501611075 | 16 G 0.75 | 13.8 | 149.1 | 325 |

| 041501811075 | 18G 0.75 | 14.4 | 166.1 | 358 |

| 041502511075 | 25G 0.75 | 16.5 | 221.4 | 475 |

| 041500200001 | 2 x 1 | 8.1 | 37.3 | 97 |

| 041500310001 | 3G 1 | 8.4 | 47.3 | 111 |

| 041500410001 | 4G 1 | 8.9 | 58.8 | 130 |

| 041500510001 | 5G 1 | 9.7 | 69.4 | 154 |

| 041500710001 | 7G 1 | 10.4 | 92.1 | 189 |

| 041501210001 | 12G 1 | 13.2 | 145.7 | 305 |

| 041501810001 | 18G 1 | 15.4 | 210.4 | 426 |

| 041502510001 | 25G 1 | 17.4 | 286.0 | 563 |

| 041500201105 | 2 x 1.5 | 8.9 | 48.2 | 120 |

| 041500311105 | 3G 1.5 | 9.3 | 64.0 | 142 |

| 041500411105 | 4G 1.5 | 10.0 | 82.3 | 172 |

| 041500511105 | 5G 1.5 | 10.5 | 96.8 | 196 |

| 041500711105 | 7G 1.5 | 11.5 | 128.8 | 247 |

| 041501211105 | 12G 1.5 | 15.2 | 216.8 | 424 |

| 041501811105 | 18G 1.5 | 17.7 | 317.5 | 598 |

| 041502511105 | 25G 1.5 | 20.7 | 426.7 | 814 |

| 041500311205 | 3G 2.5 | 10.3 | 100.7 | 194 |

| 041500411205 | 4G 2.5 | 11.3 | 129.4 | 241 |

| 041500511205 | 5G 2.5 | 12.6 | 158.5 | 298 |

| 041500711205 | 7G 2.5 | 13.9 | 211.5 | 380 |

| 041501211205 | 12 G 2.5 | 17.5 | 341.9 | 609 |

| 041501411205 | 14 G 2.5 | 18.2 | 394.5 | 684 |

| 041501410004 | 4G 4 | 13.4 | 192.3 | 347 |

| 041501410006 | 4G 6 | 15.8 | 254.9 | 477 |

| 041501410010 | 4G 10 | 19.3 | 414.4 | 737 |

| 041501410016 | 4G 16 | 22.0 | 635.7 | 1049 |

Connecting between the frequency convertor and the motor for power circuits in machine cabling. In dry damp or wet interiors with normal mechanical stress conditions. For outdoor usage within the permitted range of temperature.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041500201050 | 2 x 0.5 | 7.2 | 24.5 | 72 |

| 041500311050 | 3G 0.5 | 7.5 | 30.2 | 81 |

| 041500411050 | 4G 0.5 | 8.1 | 36.3 | 96 |

| 041500511050 | 5G 0.5 | 8.6 | 42.4 | 110 |

| 041500711050 | 7G 0.5 | 9.1 | 54.3 | 130 |

| 041501211050 | 12G 0.5 | 11.5 | 84.2 | 207 |

| 041500201075 | 2 x 0.75 | 7.6 | 30.6 | 83 |

| 041500311075 | 3G 0.75 | 8.1 | 39.5 | 99 |

| 041500411075 | 4G 0.75 | 8.6 | 47.2 | 114 |

| 041500511075 | 5G 0.75 | 9.1 | 56.6 | 132 |

| 041500711075 | 7G 0.75 | 9.9 | 71.7 | 160 |

| 041501211075 | 12G 0.75 | 12.5 | 117.1 | 261 |

| 041501611075 | 16 G 0.75 | 13.8 | 149.1 | 325 |

| 041501811075 | 18G 0.75 | 14.4 | 166.1 | 358 |

| 041502511075 | 25G 0.75 | 16.5 | 221.4 | 475 |

| 041500200001 | 2 x 1 | 8.1 | 37.3 | 97 |

| 041500310001 | 3G 1 | 8.4 | 47.3 | 111 |

| 041500410001 | 4G 1 | 8.9 | 58.8 | 130 |

| 041500510001 | 5G 1 | 9.7 | 69.4 | 154 |

| 041500710001 | 7G 1 | 10.4 | 92.1 | 189 |

| 041501210001 | 12G 1 | 13.2 | 145.7 | 305 |

| 041501810001 | 18G 1 | 15.4 | 210.4 | 426 |

| 041502510001 | 25G 1 | 17.4 | 286.0 | 563 |

| 041500201105 | 2 x 1.5 | 8.9 | 48.2 | 120 |

| 041500311105 | 3G 1.5 | 9.3 | 64.0 | 142 |

| 041500411105 | 4G 1.5 | 10.0 | 82.3 | 172 |

| 041500511105 | 5G 1.5 | 10.5 | 96.8 | 196 |

| 041500711105 | 7G 1.5 | 11.5 | 128.8 | 247 |

| 041501211105 | 12G 1.5 | 15.2 | 216.8 | 424 |

| 041501811105 | 18G 1.5 | 17.7 | 317.5 | 598 |

| 041502511105 | 25G 1.5 | 20.7 | 426.7 | 814 |

| 041500311205 | 3G 2.5 | 10.3 | 100.7 | 194 |

| 041500411205 | 4G 2.5 | 11.3 | 129.4 | 241 |

| 041500511205 | 5G 2.5 | 12.6 | 158.5 | 298 |

| 041500711205 | 7G 2.5 | 13.9 | 211.5 | 380 |

| 041501211205 | 12 G 2.5 | 17.5 | 341.9 | 609 |

| 041501411205 | 14 G 2.5 | 18.2 | 394.5 | 684 |

| 041501410004 | 4G 4 | 13.4 | 192.3 | 347 |

| 041501410006 | 4G 6 | 15.8 | 254.9 | 477 |

| 041501410010 | 4G 10 | 19.3 | 414.4 | 737 |

| 041501410016 | 4G 16 | 22.0 | 635.7 | 1049 |

In power chains or moving machine parts suitable for use in measuring, control and regulating circuits. Power circuits for electrical equipments used in automation engineering, assembly lines, production lines, in all kinds of machines and plant engineering.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 041700201050 | 2 x 0.5 | 6.7 | 25.5 | 58 |

| 041700311050 | 3G 0.5 | 7.1 | 30.6 | 67 |

| 041700511050 | 5G 0.5 | 8.2 | 42.3 | 90 |

| 041700611050 | 6 G 0.5 | 8.7 | 49.2 | 103 |

| 041700711050 | 7G 0.5 | 9.5 | 53.7 | 120 |

| 041701211050 | 12G 0.5 | 10.9 | 84.2 | 168 |

| 041701811050 | 18G 1 | 12.9 | 210.4 | 313 |

| 041702011050 | 20 G 0.5 | 13.5 | 128.1 | 259 |

| 041702511050 | 25G 0.5 | 15.0 | 156.9 | 319 |

| 041703011050 | 30 G 0.5 | 15.8 | 181.7 | 362 |

| 041703611050 | 36 G 0.5 | 16.9 | 214.5 | 420 |

| 041700201075 | 2 x 0.75 | 7.2 | 30.6 | 67 |

| 041700311075 | 3G 0.75 | 7.6 | 39.5 | 80 |

| 041700411075 | 4G 0.75 | 8.3 | 47.2 | 96 |

| 041700511075 | 5G 0.75 | 8.9 | 56.6 | 113 |

| 041700711075 | 7G 0.75 | 10.6 | 71.7 | 155 |

| 041701211075 | 12G 0.75 | 12.1 | 117.1 | 220 |

| 041701811075 | 18G 0.75 | 14.6 | 166.1 | 319 |

| 041702511075 | 25G 0.75 | 17.7 | 221.4 | 452 |

| 041703611075 | 36G 0.75 | 19.4 | 306.5 | 576 |

| 041700200001 | 2 x 1 | 7.6 | 37.3 | 78 |

| 041700310001 | 3G 1 | 8.1 | 47.3 | 94 |

| 041700410001 | 4G 1 | 8.8 | 58.8 | 114 |

| 041700510001 | 5G 1 | 9.6 | 69.4 | 135 |

| 041700710001 | 7G 1 | 11.3 | 92.1 | 185 |

| 041701210001 | 12G 1 | 13.2 | 145.7 | 269 |

| 041701810001 | 18G 1 | 15.9 | 210.4 | 392 |

| 041702510001 | 25G 1 | 19.5 | 286.0 | 568 |

| 041703010001 | 30 G 1 | 19.6 | 335.1 | 612 |

| 041703610001 | 36 G 1 | 21.2 | 397.8 | 722 |

| 041700201105 | 2 x 1.5 | 8.9 | 48.2 | 106 |

| 041700311105 | 3G 1.5 | 9.3 | 64.0 | 126 |

| 041700411105 | 4G 1.5 | 10.0 | 82.0 | 153 |

| 041700511105 | 5G 1.5 | 10.5 | 96.8 | 172 |

| 041700711105 | 7G 1.5 | 11.5 | 128.8 | 219 |

| 041701211105 | 12G 1.5 | 15.2 | 223.8 | 385 |

| 041701811105 | 18G 1.5 | 17.7 | 317.5 | 535 |

| 041702511105 | 25G 1.5 | 20.3 | 426.7 | 709 |

| 041703611105 | 36 G 1.5 | 22.7 | 593.0 | 938 |

| 041700311205 | 3G 2.5 | 10.7 | 96.6 | 178 |

| 041700411205 | 4G 2.5 | 11.7 | 123.6 | 220 |

| 041700511205 | 5G 2.5 | 12.8 | 151.0 | 266 |

| 041700711205 | 7G 2.5 | 14.0 | 211.5 | 344 |

| 041701211205 | 12 G 2.5 | 17.5 | 346.5 | 553 |

| 041701811205 | 18G 2.5 | 20.2 | 499.1 | 771 |

| 041702511205 | 25G 2.5 | 23.6 | 675.3 | 1044 |

Machine tools, industrial machinery, Measurement control, and electrical applications. Very suitable for oily wet areas within machinery and production shop floor that are subject to normal mechanical stress. Resistant to contact with mineral oil-based lubricants, diluted acids, aqueous alkaline solutions and other chemical media. Outdoor use is possible within the indicated temperature range.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

|---|---|---|---|---|

| 040100201050 | 2 x 0.5 | 4.8 | .7 | 30 |

| 040100311050 | 3G 0.5 | 5.1 | 3.0 | 37 |

| 040100301050 | 3 x 0.5 | 5.1 | 3.0 | 37 |

| 040100411050 | 4G 0.5 | 5.6 | 7.4 | 46 |

| 040100401050 | 4 x 0.5 | 5.6 | 7.4 | 46 |

| 040100511050 | 5G 0.5 | 6.0 | 1.7 | 55 |

| 040100501050 | 5 x 0.5 | 6.0 | 1.7 | 55 |

| 040100711050 | 7G 0.5 | 6.7 | 0.4 | 72 |

| 040100701050 | 7 x 0.5 | 6.7 | 0.4 | 72 |

| 040101011050 | 10G 0.5 | 8.8 | 3.5 | 115 |

| 040101211050 | 12G 0.5 | 8.9 | 2.2 | 126 |

| 040101811050 | 18G 0.5 | 10.5 | 78.2 | 180 |

| 040102511050 | 25G 0.5 | 12.9 | 108.6 | 263 |

| 040103411050 | 34G 0.5 | 14.3 | 147.8 | 337 |

| 040104211050 | 42G 0.5 | 16.6 | 182.5 | 437 |

| 040100201075 | 2 x 0.75 | 5.3 | 13.0 | 39 |

| 040100311075 | 3G 0.75 | 5.6 | 19.6 | 48 |

| 040100301075 | 3 x 0.75 | 5.6 | 19.6 | 48 |

| 040100411075 | 4G 0.75 | 6.1 | 26.1 | 59 |

| 040100401075 | 4 x 0.75 | 6.1 | 26.1 | 59 |

| 040100511075 | 5G 0.75 | 6.9 | 32.6 | 76 |

| 040100501075 | 5 x 0.75 | 6.9 | 32.6 | 76 |

| 040100711075 | 7G 0.75 | 7.6 | 45.6 | 97 |

| 040100701075 | 7 x 0.75 | 7.6 | 45.6 | 97 |

| 040101011075 | 10G 0.75 | 10.0 | 5.2 | 156 |

| 040101211075 | 12G 0.75 | 10.1 | 8.2 | 171 |

| 040101811075 | 18G 0.75 | 11.9 | 17.3 | 247 |

| 040102511075 | 25G 0.75 | 14.6 | 63.0 | 357 |

| 040103411075 | 34G 0.75 | 15.7 | 21.6 | 446 |

| 040104111075 | 41G 0.75 | 17.4 | 67.3 | 543 |

| 040100200001 | 2 x 1 | 5.6 | 17.4 | 46 |

| 040100310001 | 3G 1 | 6.0 | 26.1 | 59 |

| 040100300001 | 3 x 1 | 6.0 | 26.1 | 59 |

| 040100410001 | 4G 1 | 6.8 | 34.8 | 77 |

| 040100400001 | 4 x 1 | 6.8 | 34.8 | 77 |

| 040100510001 | 5G 1 | 7.5 | 43.5 | 93 |

| 040100500001 | 5 x 1 | 7.5 | 43.5 | 93 |

| 040100710001 | 7G 1 | 8.9 | 60.8 | 132 |

| 040101010001 | 10G 1 | 10.8 | 86.9 | 191 |

| 040101210001 | 12G 1 | 11.1 | 104.3 | 215 |

| 040101810001 | 18G 1 | 13.2 | 156.5 | 311 |

| 040102510001 | 25G 1 | 16.2 | 217.3 | 452 |

| 040103410001 | 34G 1 | 18.1 | 295.5 | 587 |

| 040104110001 | 41G 1 | 19.7 | 356.4 | 700 |

| 040100201105 | 2 x 1.5 | 6.3 | 25.5 | 61 |

| 040100311105 | 3G 1.5 | 6.7 | 38.2 | 78 |

| 040100301105 | 3 x 1.5 | 6.7 | 38.2 | 78 |

| 040100411105 | 4G 1.5 | 7.3 | 50.9 | 98 |

| 040100401105 | 4 x 1.5 | 7.3 | 50.9 | 98 |

| 040100511105 | 5G 1.5 | 8.2 | 63.7 | 123 |

| 040100501105 | 5 x 1.5 | 8.2 | 63.7 | 123 |

| 040100711105 | 7G 1.5 | 9.0 | 89.1 | 160 |

| 040100701105 | 7 x 1.5 | 9.0 | 89.1 | 160 |

| 040101211105 | 12G 1.5 | 12.1 | 152.8 | 280 |

| 040101811105 | 18G 1.5 | 14.5 | 229.2 | 412 |

| 040102511105 | 25G 1.5 | 17.2 | 318.3 | 576 |

| 040103411105 | 34G 1.5 | 19.6 | 432.9 | 766 |

| 040104111105 | 41G 1.5 | 21.3 | 522.0 | 915 |

| 040100201205 | 2 x 2.5 | 7.6 | 42.4 | 93 |

| 040100311205 | 3G 2.5 | 8.3 | 63.7 | 124 |

| 040100411205 | 4G 2.5 | 9.1 | 84.9 | 157 |

| 040100511205 | 5G 2.5 | 10.2 | 106.1 | 196 |

| 040100711205 | 7G 2.5 | 11.2 | 148.5 | 256 |

| 040101211205 | 12G2.5 | 14.8 | 254.6 | 443 |

| 040100410004 | 4G 4 | 10.8 | 135.0 | 234 |

| 040100510004 | 5G 4 | 12.1 | 168.7 | 292 |

| 040100710004 | 7G 4 | 13.3 | 236.2 | 383 |

| 040100410006 | 4G 6 | 13.0 | 202.4 | 345 |

| 040100510006 | 5G 6 | 14.5 | 253.1 | 430 |

| 040100710006 | 7G 6 | 16.0 | 354.3 | 566 |

| 040100410010 | 4G 10 | 15.5 | 344.7 | 539 |

| 040100510010 | 5G 10 | 17.1 | 430.8 | 666 |

| 040100710010 | 7G 10 | 19.0 | 603.2 | 888 |

| 040100410016 | 4G 16 | 18.8 | 574.1 | 852 |