Application :-

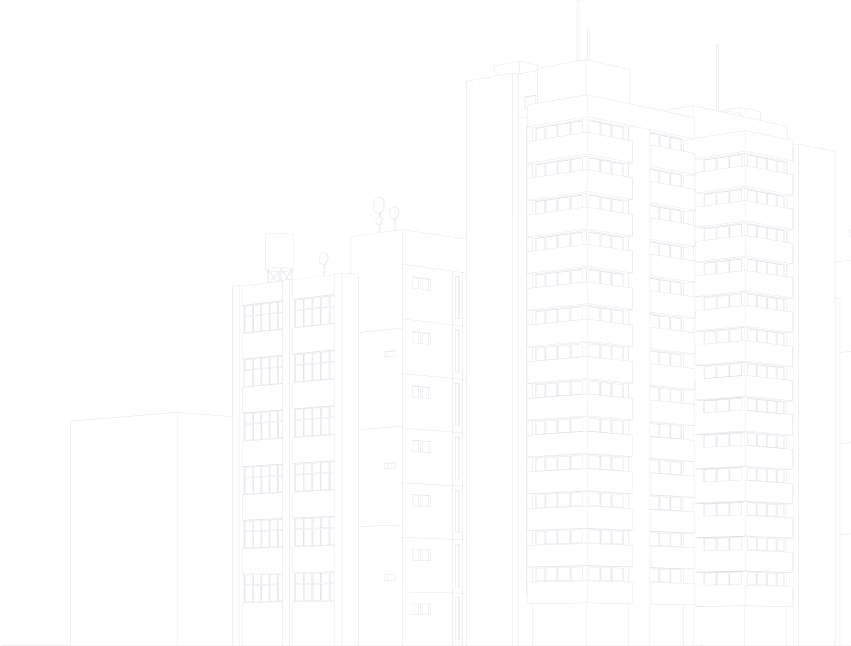

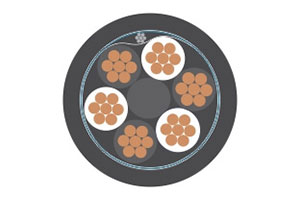

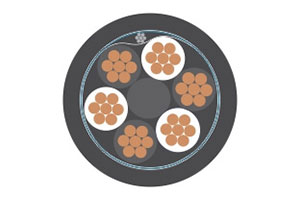

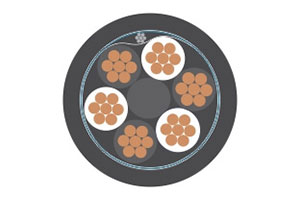

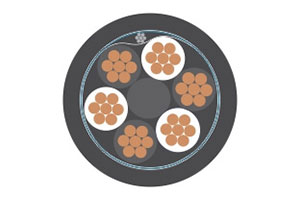

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white

core (1, 2, 3…) for multi-element

- Wrapping : 1 layer of PETP tape

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

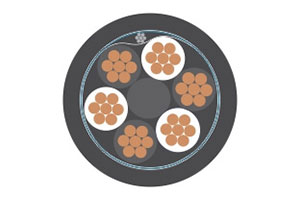

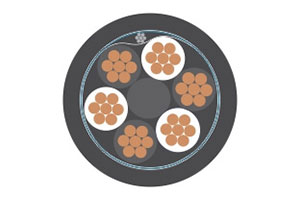

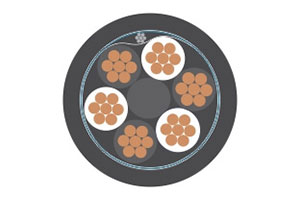

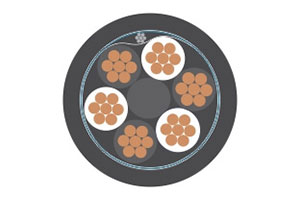

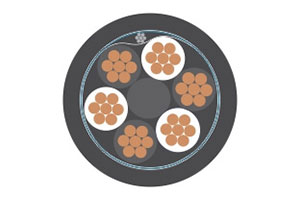

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white

core (1, 2, 3…) for multi-element

- Individual Screen : Aluminium / PETP tape over tinned copper drain wire,

plastic tape under and above screen

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white

core (1, 2, 3…) for multi-element

- Individual Screen : Aluminium / PETP tape over tinned copper drain wire,

plastic tape under and above screen

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white

core (1, 2, 3…) for multi-element

- Individual Screen : Aluminium / PETP tape over tinned copper drain wire,

plastic tape under and above screen

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Crosslinked polyethylene XLPE

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white core (1, 2, 3…) for multi-element

- Wrapping : 1 layer of PETP tape

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Crosslinked polyethylene XLPE

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white core (1, 2, 3…) for multi-element

- Wrapping : 1 layer of PETP tape

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Crosslinked polyethylene XLPE

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white core (1, 2, 3…) for multi-element

- Wrapping : 1 layer of PETP tape

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Crosslinked polyethylene XLPE

- Pairs : Twisted

- Identification Pairs : Black & white, continuously numbered on white core (1, 2, 3…) for multi-element

- Wrapping : 1 layer of PETP tape

- Assembly : Concentric layers

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +70°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL n x m x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- n – No. of pairs, m – Pairs, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Individual Screen : Aluminium / PETP tape over tinned copper drain wire, plastic tape under and above screen

- Colour Code : Black, continuously numbered in white

- Wrapping : 1 layer of PETP tape

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +90°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL c x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- c – No. of cores, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Cross-linked polyethylene XLPE

- Individual Screen : Aluminium / PETP tape over tinned copper drain wire, plastic tape under and above screen

- Colour Code : Black, continuously numbered in white

- Wrapping : 1 layer of PETP tape

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Cable Sheath : Polyvinyl chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +90°C

- Bending Radius : 7.5 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL c x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- c – No. of cores, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Polyvinyl chloride PVC

- Colour Code : Black, continuously numbered in white

- Wrapping : 1 layer of PETP tape

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl Chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +90°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL c x a RE-Y(St)Y 500V EN 50288-7 CE + 0001m

- c – No. of cores, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |

Application :-

Cable Construction :-

- Conductor : Annealed copper wires according to BS EN 60228

- Insulation : Cross-linked polyethylene XLPE

- Colour Code : Black, continuously numbered in white

- Wrapping : 1 layer of PETP tape

- Collective Screen : Aluminium / PETP tape over tinned copper drain wire

- Inner Sheath : Polyvinyl Chloride PVC

- Armour : Galvanised round steel wires

- Cable Sheath : Polyvinyl Chloride PVC

- Colour : Black. Blue for intrinsically safe system

Technical Data :-

- Flame Propagation : EN 60332-1-2

- Operating Temperature Range : -30°C to +90°C

- Bending Radius : 10 x cable diameter

- Operating Voltage : 500V

- *Also available in 300V variant on request

- Marking : RR KABEL c x a RE-2X(St)YSWAY 500V EN 50288-7 CE + 0001m

- c – No. of cores, a – Cross sectional area

| Conductor Cross Section (Sq.mm) |

Class of Conductor |

No. of Strands/Max. Strand Diameter (mm) |

Max. DC Conductor Resistance* at 20°C (Ω/km) |

Max.L/R Ratio (μH/Ω) |

Min. Insulation Resistance (GΩ x cm) |

Max. Mutual Capacitance (nF/km) |

Max.Inductance (mH/km) |

Test Voltage Vrms (Core-Core) |

Test Voltage Vrms (Core-Screen) |

| 0.5 |

2 |

7/0.3 |

36.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.5 |

5 |

16/0.2 |

39.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

2 |

7/0.37 |

24.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 0.75 |

5 |

24/0.2 |

26.0 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

2 |

7/0.43 |

18.1 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1 |

5 |

32/0.2 |

19.5 |

25 |

20 |

250 |

1 |

2000 |

2000 |

| 1.5 |

2 |

7/0.53 |

12.1 |

40 |

20 |

250 |

1 |

2000 |

2000 |

| 2.5 |

2 |

7/0.67 |

7.41 |

60 |

20 |

250 |

1 |

2000 |

2000 |