RATNAFLEX MULTICORE (IS 694)

Application :-

- Cable designed for internal wiring in switch control, relay and

instrumentation panels of power switchgear and for purposes such as

stationary, static appliances, internal connectors in rectifier

equipment, motor starters and controllers.

- PVC 70°C cables suitable for general wiring in control cabinets,

panels

and power switchgear.

- FR PVC 70°C cables suitable for ambient wiring in control cabinets,

panels and power switchgear for enhanced safety.

- HR PVC 70°C cables suitable for higher ambient wiring in control

cabinets, panels and power switchgear.

- HR FR PVC 85°C cables suitable for higher ambient wiring in control

cabinets, panels and power switchgear and enhanced safety.

- FR-LSH PVC cables are suitable for wiring in public places like

schools,

hospitals, theatres, etc. These are also suitable for fire prone

areas

in industries and commercial infrastructure.

- HFFR cables, suitable for critical and dense wiring for utmost

safety of

public like schools, hospitals, theatres, etc. These are also

suitable

for fire prone areas.

Technical Data :-

- Approvals : IS 694 marked, FIA / TAC

- Conductor : Electrolytic grade annealed copper

- Voltage : Up to and including 1100V

- Packing : Standard packing of 100 mtr. in coil. Longer length

available

on request

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix

(in place of ‘xx’) for the colour required: 01 – green, 02 – black,

03 –

red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 – white, 08 –

violet,

09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘y’) for the insulation material

required: 1 – PVC 70°C, 2 – PVC FR 70°C, 3 – PVC HR 85°C, 4 – PVC HR

85°C +FR, 5 – PVC FR-LSH, 7 – HFFR.

| Part Number |

Nominal Cross Sectional Area (Sq. mm) |

No of Strands/Max. Strand Diameter (mm) |

Nominal Insulation Thickness (mm) |

Maximum Diameter Over Insulation (mm) |

| 02010101xxy0 |

0.5 |

16/0.2 |

0.6 |

2.6 |

| 02010102xxy0 |

0.75 |

24/0.2 |

0.6 |

2.8 |

| 02010103xxy0 |

1 |

32/0.2 |

0.6 |

3.0 |

| 02010104xxy0 |

1.5 |

30/0.25 |

0.7 |

3.4 |

| 02010105xxy0 |

2.5 |

50/0.25 |

0.8 |

4.1 |

| 02010106xxy0 |

4 |

56/0.3 |

0.8 |

4.8 |

| 02010107xxy0 |

6 |

84/0.3 |

0.8 |

5.3 |

| 02010108xxy0 |

10 |

140/0.3 |

1.0 |

7.0 |

| 02010109xxy0 |

16 |

126/0.4 |

1.0 |

8.1 |

| 02010110xxy0 |

25 |

196/0.4 |

1.2 |

10.2 |

| 02010111xxy0 |

35 |

276/0.4 |

1.2 |

11.7 |

| 02010112xxy0 |

50 |

396/0.4 |

1.4 |

13.9 |

| 02010113xxy0 |

70 |

360/0.5 |

1.4 |

16.0 |

| 02010114xxy0 |

95 |

480/0.5 |

1.6 |

18.2 |

| 02010115xxy0 |

120 |

608/0.5 |

1.6 |

20.2 |

| 02010116xxy0 |

150 |

750/0.5 |

1.8 |

22.5 |

| 02010117xxy0 |

185 |

931/0.5 |

2.0 |

24.9 |

| 02010118xxy0 |

240 |

1200/0.5 |

2.2 |

28.4 |

| 02010119xxy0 |

300 |

1500/0.5 |

2.4 |

31.0 |

Application :-

- Cable designed for internal wiring in switch control, relay and

instrumentation panels of power switchgear and for purposes such as

Stationary, static appliances, internal connectors in rectifier

equipment, motor starters and controllers.

Standard :-

- DIN EN 50525-2-31, VDE 0285-525-2-31, BS EN 50525-2-31.

Technical Data :-

- Voltage Rating : 0.5 to 1 mm² – 300 / 500V, 1.5 to 240 mm² – 450 /

750V

- Temperature Range : -30°C to +70°C

- Minimum Bending Radius : Cable diameter ≤ 8 mm : 4 x outer diameter,

Approx. diameter > 8 to 12 mm : 5 x outer diameter, Approx. diameter

> 12 mm : 6 x outer diameter

- Test Voltage : 2500V

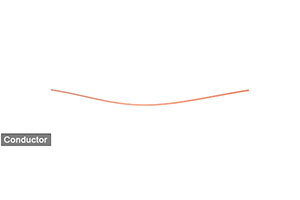

Cable Construction :-

- Conductor Class 5 flexible plain / metal coated stranded according

to EN 60228. Insulation PVC (Polyvinyl chloride) TI1 to BS EN 50363-

3.

Properties :-

- PVC self-extinguishing and flame retardant according to EN

60332-1-2.

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix (in place of ‘xx’) for the colour required: 01 – green, 02 –

black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘c’) for the conductor type

required: 0 = Annealed Bare Copper (ABC), 1 = Annealed Tinned Copper

(ATC)

|

Nominal CrossSectional Area (Sq. mm)

|

Nominal Thickness of Insulation (mm)

|

Mean Overall Diameter |

Approx. Cable Weight (kg/km) |

| Lower Limit (mm) |

Upper Limit (mm) |

| -H05VK |

02020101xx1c |

0.5 |

0.6 |

2.1 |

2.5 |

9 |

| 02020102xx1c |

0.75 |

0.6 |

2.2 |

2.7 |

12 |

| 02020103xx1c |

1.0 |

0.6 |

2.4 |

2.8 |

15 |

| -H07VK |

02020104xx1c |

1.5 |

0.7 |

2.8 |

3.4 |

21 |

| 02020105xx1c |

2.5 |

0.8 |

3.4 |

4.1 |

33 |

| 02020106xx1c |

4 |

0.8 |

3.9 |

4.8 |

47 |

| 02020107xx1c |

6 |

0.8 |

4.4 |

5.3 |

66 |

| 02020108xx1c |

10 |

1.0 |

5.7 |

6.8 |

112 |

| 02020109xx1c |

16 |

1.0 |

6.7 |

8.1 |

170 |

| 02020110xx1c |

25 |

1.2 |

8.4 |

10.2 |

261 |

| 02020110xx1c |

25 |

1.2 |

8.4 |

10.2 |

261 |

| 02020111xx1c |

35 |

1.2 |

9.7 |

11.7 |

358 |

| 02020112xx1c |

50 |

1.4 |

11.5 |

13.9 |

510 |

| 02020113xx1c |

70 |

1.4 |

13.2 |

16.0 |

927 |

| 02020114xx1c |

95 |

1.6 |

15.1 |

18.2 |

510 |

| 02020115xx1c |

120 |

1.6 |

16.7 |

20.2 |

1170 |

| 02020116xx1c |

150 |

1.8 |

18.6 |

22.5 |

1459 |

| 02020117xx1c |

185 |

2.0 |

20.6 |

24.9 |

1776 |

| 02020118xx1c |

240 |

2.2 |

23.5 |

28.4 |

2333 |

Application :-

- Heat resistant cable designed for internal wiring in switch control,

relay and instrumentation panels of power switch gear and for

purposes such as internal connectors in rectifier equipment, motor

starters and controllers.

Standard :-

Technical Data :-

- Voltage Rating : 0.5 to 1 mm² – 300 / 500V, 1.5 to 240 mm² – 450 /

750V

- Temperature Range : -30°C to +70°C

- Minimum Bending Radius : Cable diameter ≤ 8 mm : 4 x outer diameter,

Approx. diameter > 8 to 12 mm : 5 x outer diameter, Approx. diameter

> 12 mm : 6 x outer diameter

- Test Voltage : 2500V

Cable Construction :-

- Conductor Class 5 flexible plain / metal coated stranded according

to EN 60228. Insulation PVC (Polyvinyl chloride) TI1 to BS EN 50363-

3.

Properties :-

- PVC self-extinguishing and flame retardant according to EN

60332-1-2.

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix (in place of ‘xx’) for the colour required: 01 – green, 02 –

black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘c’) for the conductor type

required: 0 = Annealed Bare Copper (ABC), 1 = Annealed Tinned Copper

(ATC)

|

Nominal CrossSectional Area (Sq. mm)

|

Nominal Thickness of Insulation (mm)

|

Mean Overall Diameter |

Approx. Cable Weight (kg/km) |

| Lower Limit (mm) |

Upper Limit (mm) |

| H05V2K- |

|

0.5 |

0.6 |

2.1 |

2.5 |

8.5 |

| 02030102xx3c |

0.75 |

0.6 |

2.2 |

2.7 |

11.5 |

| 02030103xx3c |

1 |

0.6 |

2.4 |

2.8 |

13.5 |

| H07V2K- |

02030104xx3c |

1.5 |

0.7 |

2.8 |

3.4 |

20 |

| 02030105xx3c |

2.5 |

0.8 |

3.4 |

4.1 |

32 |

| 02030106xx3c |

4 |

0.8 |

3.9 |

4.8 |

46 |

| 02030107xx3c |

6 |

0.8 |

4.4 |

5.3 |

65 |

| 02030108xx3c |

10 |

1.0 |

5.7 |

6.8 |

110 |

| 02030109xx3c |

16 |

1.0 |

6.7 |

8.1 |

167 |

| 02030110xx3c |

25 |

1.2 |

8.4 |

10.2 |

257 |

| 02030111xx3c |

35 |

1.2 |

9.7 |

11.7 |

358 |

Application :-

- Halogen-free single-core wires are used for installation in dry

environments for wiring up lighting fixtures and units where

valuable assets are to protected from further damage resulting from

fire. These cables may be installed on, in and beneath plaster, as

well as in closed installation ducts. The direct operating voltages

is permitted up to 900 V against ground when they are used in

rail-coaches. For the inner wiring of switch boards and distributors

are to be used with an alternating nominal voltage up to 1000V or a

direct voltage up to 750V against ground.

Technical Data :-

- Nominal Voltage : H05Z-K U / U 300 / 500V, H07Z-K U / U 450 / 750V O

O

- Harmonised Designation : 0.5 mm2 to 1 mm2 – H05Z-K, 1.5 mm2 to 240

mm2 – H07Z-K

- Temperature Range : -15°C to +90°C

- Minimum Bending Radius : Cable diameter ≤ 8 mm : 4 x outer diameter,

Approx. diameter > 8 to 12 mm : 5 x outer diameter, Approx. diameter

> 12 mm : 6 x outer diameter

- Test Voltage : 2500V

Standard :-

Cable Construction :-

- Conductor Class 5 flexible plain/metal coated stranded according to

EN 60228. Insulation Polyolefin cross linked EI5 to EN 50363-5.

Tests :-

- Smoke density to acc. to EN 61034-2.

- Halogen free acc. to EN 50525-1, EN 60754-1.

- Corrosivity acc. to EN 60754-2 Ozone resistant according to EN

60811-2-1.

- Self-extinguishing and flame retardant according to EN 60332-1-2.

- LSOH = Low Smoke Zero Halogen-Free.

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix (in place of ‘xx’) for the colour required: 01 – green, 02 –

black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘c’) for the conductor type

required: 0 = Annealed Bare Copper (ABC), 1 = Annealed Tinned Copper

(ATC)

|

Nominal Cross Sectional Area (Sq. mm)

|

Nominal Thickness of Insulation (mm)

|

Mean Overall Diameter |

Approx. Cable Weight (kg/km) |

| Lower Limit (mm) |

Upper Limit (mm) |

| H05V2K- |

02040101xx6c |

0.5 |

0.6 |

1.9 |

2.4 |

9 |

| 02040102xx6c |

0.75 |

0.6 |

2.1 |

2.6 |

12 |

| 02040103xx6c |

1 |

0.6 |

2.1 |

2.8 |

15 |

| H07V2K- |

02040104xx6c |

1.5 |

0.7 |

2.8 |

3.5 |

21 |

| 02040105xx6c |

2.5 |

0.8 |

3.4 |

4.3 |

33 |

| 02040106xx6c |

4 |

0.8 |

3.9 |

4.9 |

47 |

| 02040107xx6c |

6 |

0.8 |

4.4 |

5.5 |

66 |

| 02040108xx6c |

10 |

1.0 |

5.7 |

7.1 |

112 |

| 02040109xx6c |

16 |

1.0 |

6.7 |

8.4 |

169 |

| 02040110xx6c |

25 |

1.2 |

8.4 |

10.6 |

260 |

| 02040111xx6c |

35 |

1.2 |

9.7 |

12.1 |

358 |

| 02040112xx6c |

50 |

1.4 |

11.5 |

14.4 |

509 |

| 02040113xx6c |

70 |

1.4 |

13.2 |

16.61 |

701 |

| 02040114xx6c |

95 |

1.6 |

15.1 |

18.8 |

925 |

| 02040115xx6c |

120 |

1.6 |

16.7 |

20.9 |

1168 |

| 02040116xx6c |

150 |

1.8 |

18.6 |

23.3 |

1456 |

| 02040117xx6c |

185 |

2.0 |

20.6 |

25.8 |

1773 |

| 02040118xx6c |

240 |

2.2 |

23.5 |

29.4 |

2329 |

Application :-

- Halogen-free single-core wires are used for installation in dry

environments for wiring up lighting fixtures and units where

valuable asset are to protected from further damage resulting from

fire. These cables may be installed on, in and beneath plaster, as

well as in close installation ducts. For use in public places such

as: hospitals, schools, museums, airports, bus terminals, shops in

general, etc., as well a in computer rooms, offices, production

plants, switchboard wiring, laboratories, etc.

Technical Data :-

- Nominal Voltage : H05Z-K U / U 300 / 500V, H07Z-K U / U 450 / 750V O

O

- Harmonised Designation : 0.5 mm2 to 1 mm2 – H05Z-K, 1.5 mm2 to 240

mm2 – H07Z-K

- Temperature Range : -30°C to +70°C

- Minimum Bending Radius : Cable diameter ≤ 8 mm : 4 x outer diameter,

Approx. diameter > 8 to 12 mm : 5 x outer diameter, Approx. diameter

> 12 mm : 6 x outer diameter

- Test Voltage : 2500V

Standard :-

Cable Construction :-

- Conductor Class 5 flexible plain / metal coated stranded according

to EN 60228. *Core insulation of thermoplastic halogen-free compound

type TI7 to EN 50363-7.

Tests :-

- Smoke density to acc. to EN 61034-2.

- Halogen free acc. to EN 50525-1, EN 60754-1.

- Corrosivity acc. to EN 60754-2 Ozone resistant according to EN

60811-2-1.

- Self-extinguishing and flame retardant according to EN 60332-1-2.

- LSOH = Low Smoke Zero Halogen-Free.

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix (in place of ‘xx’) for the colour required: 01 – green, 02 –

black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘c’) for the conductor type

required: 0 = Annealed Bare Copper (ABC), 1 = Annealed Tinned Copper

(ATC)

|

Nominal Cross Sectional Area (Sq. mm)

|

Nominal Thickness of Insulation (mm)

|

Mean Overall Diameter |

Approx. Cable Weight (kg/km) |

| Lower Limit (mm) |

Upper Limit (mm) |

| H05V2K- |

02040101xx6c |

0.5 |

0.6 |

1.9 |

2.4 |

9 |

| 02040102xx6c |

0.75 |

0.6 |

2.1 |

2.6 |

12 |

| 02040103xx6c |

1 |

0.6 |

2.1 |

2.8 |

15 |

| H07V2K- |

02040104xx6c |

1.5 |

0.7 |

2.8 |

3.5 |

21 |

| 02040105xx6c |

2.5 |

0.8 |

3.4 |

4.3 |

33 |

| 02040106xx6c |

4 |

0.8 |

3.9 |

4.9 |

47 |

| 02040107xx6c |

6 |

0.8 |

4.4 |

5.5 |

66 |

| 02040108xx6c |

10 |

1.0 |

5.7 |

7.1 |

112 |

| 02040109xx6c |

16 |

1.0 |

6.7 |

8.4 |

169 |

| 02040110xx6c |

25 |

1.2 |

8.4 |

10.6 |

260 |

| 02040111xx6c |

35 |

1.2 |

9.7 |

12.1 |

358 |

| 02040112xx6c |

50 |

1.4 |

11.5 |

14.4 |

509 |

| 02040113xx6c |

70 |

1.4 |

13.2 |

16.61 |

701 |

| 02040114xx6c |

95 |

1.6 |

15.1 |

18.8 |

925 |

| 02040115xx6c |

120 |

1.6 |

16.7 |

20.9 |

1168 |

| 02040116xx6c |

150 |

1.8 |

18.6 |

23.3 |

1456 |

| 02040117xx6c |

185 |

2.0 |

20.6 |

25.8 |

1773 |

| 02040118xx6c |

240 |

2.2 |

23.5 |

29.4 |

2329 |

Application :-

- High temperature, flame retardant cable designed for use in switch

control, relay and instrumentation panels of power switchgear and

for purposes such as internal connectors in rectifier equipment,

motor starters and controllers.

Technical Data :-

- Voltage Rating : 600 / 1000V

- Temperature Rating : 90°C (105°C for 15,000 hours)

- Minimum Bending Radius : Cable diameter ≤8 mm : 4 x outer diameter.,

Approx. diameter > 8 to 12 mm: 5 x outer diameter., Approx. diameter

> 12 mm: 6 x outer diameter.

- Test Voltage : 2500V

Standard :-

Cable Construction :-

- Conductor : Conductor Class 5 flexible plain/metal coated stranded

according to EN 60228 cl. 5. Insulation : PVC (Polyvinyl Chloride)

TI3 to BS EN 50363-3.

Properties :-

- PVC self-extinguishing and flame retardant according to EN

60332-1-2.

Cable Design Parameters :-

- Kindly complete the part numbers for these cables by adding the

suffix (in place of ‘xx’) for the colour required: 01 – green, 02 –

black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 –

white, 08 – violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey.

- By adding the suffix (in place of ‘c’) for the conductor type

required: 0 = Annealed Bare Copper (ABC), 1 = Annealed Tinned Copper

(ATC)

| Part Number |

Nominal Cross Sectional Area (Sq. mm)

|

Nominal Thickness of Insulation (mm)

|

Mean Overall Diameter |

Approx. Cable Weight (kg/km) |

| Lower Limit (mm) |

Upper Limit (mm) |

| 02060101xx3c |

0.5 |

0.8 |

2.4 |

3.0 |

11 |

| 02060102xx3c |

0.75 |

0.8 |

2.6 |

3.1 |

14 |

| 02060103xx3c |

1 |

0.8 |

2.7 |

3.3 |

16 |

| 02060104xx3c |

1.5 |

0.8 |

3.0 |

3.6 |

21 |

| 02060105xx3c |

2.5 |

0.8 |

3.4 |

4.1 |

32 |

| 02060106xx3c |

4 |

0.8 |

3.9 |

4.8 |

46 |

| 02060107xx3c |

6 |

0.8 |

4.4 |

5.3 |

64 |

| 02060108xx3c |

10 |

1.0 |

5.7 |

7.2 |

109 |

| 02060109xx3c |

16 |

1.0 |

6.7 |

9.0 |

166 |

| 02060110xx3c |

25 |

1.2 |

8.4 |

11.5 |

256 |

| 02060111xx3c |

35 |

1.2 |

9.7 |

12.5 |

352 |

| 02060112xx3c |

50 |

1.4 |

11.5 |

15.4 |

501 |

| 02060113xx3c |

70 |

1.4 |

13.2 |

17.5 |

692 |

| 02060114xx3c |

95 |

1.6 |

15.1 |

19.2 |

914 |

| 02060115xx3c |

120 |

1.6 |

16.7 |

21.2 |

1155 |

| 02060116xx3c |

150 |

1.8 |

18.6 |

23.9 |

1441 |

| 02060117xx3c |

185 |

2.0 |

20.6 |

25.9 |

1754 |

| 02060118xx3c |

240 |

2.2 |

23.5 |

28.9 |

2305 |